Pulsation dampeners are auxiliary devices used to reduce the vibration of a reciprocating pump or compressor. It works by providing a limited, controlled flow of liquid or gas to and from the pump or compressor, thus dampening pulsations. The dampener helps maintain an even pressure throughout the system and prevents damage to machinery from excessive vibrations. Pulse dampeners can also be used on pressure gauges to minimize pointer bounce which makes it easier to read the instrument.

Pulsation dampeners are installed in a variety of industrial applications, including oil and gas production, water treatment, HVAC systems, pumping applications, process piping systems and chemical/petrochemical processes. They play an important role in the reliable operation of these systems, as pulsations can cause noise and vibration issues that can damage equipment and reduce productivity.

What Materials are Pulsation Dampeners Made of?

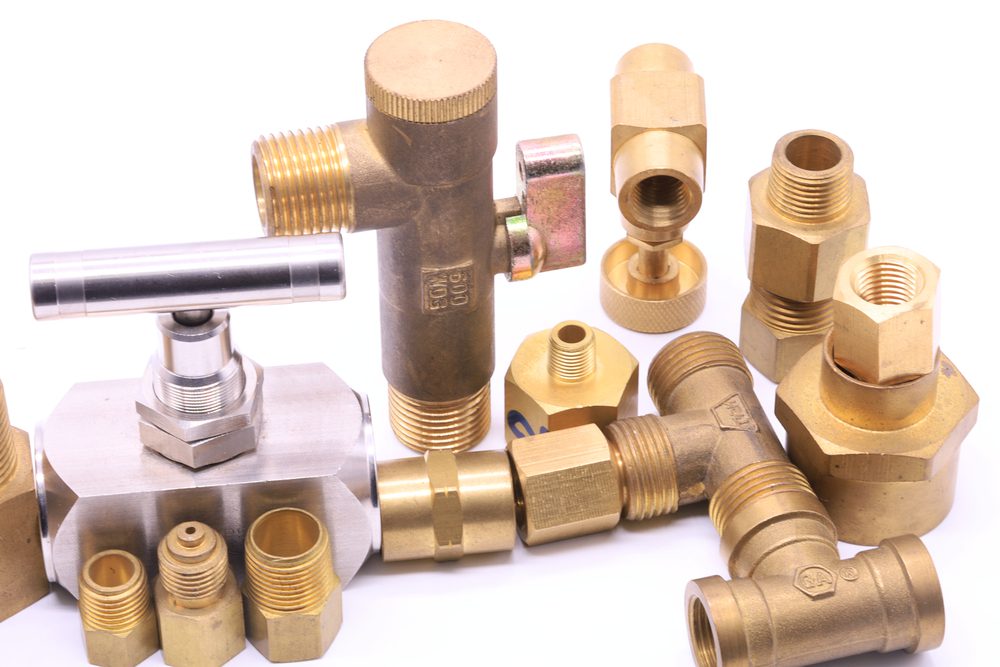

Pulsation dampeners come in a variety of sizes, shapes and materials. They can be made of steel, aluminum, plastic or stainless steel depending on the application and the environment in which they will be used.

Let’s take a closer look at two of the most popular materials on the market: brass and stainless steel.

Brass

Brass is an alloy of copper and zinc with a shiny, gold-like hue. Its composition can range anywhere between 50-63% copper and 50-37% zinc, with other additives sometimes used for malleability. Brass is a great choice for low-pressure applications, as it’s very strong and has good corrosion resistance.

Stainless Steel

Stainless steel is an alloy of iron, chromium, nickel and other metals. The metal is known for its strength and durability, as well as its ability to resist corrosion. It is often used in food processing applications, chemical processing and other industries where hygiene is essential.

What are the Differences Between Brass and Stainless Steel Pulsation Dampeners?

When deciding which material to use for a pulsation dampener, there are several factors that need to be taken into consideration. Brass and stainless steel pulsation dampeners both have their advantages and disadvantages. The most notable differences between brass and stainless steel pulsation dampeners are corrosion resistance, cost and strength.

Brass is more prone to corrosion than stainless steel and is therefore not recommended for systems where aggressive chemicals may be present. It is generally cheaper than its counterpart, but not as strong.

Stainless steel is harder than brass and also has a higher melting point. Some find it slightly harder than brass to cast and machine, a tradeoff for better strength and corrosion resistance. It is more expensive than brass, but it can still be very cost effective in certain applications.

As far as pulsation dampeners go, both stainless steel and brass can be viable materials to go with. Making the right decision comes down to a consideration of your specific use case and what demands are placed on the system.

Mid-West Instrument

Buying your pulsation dampener from a reputable manufacturer is the best way to ensure that you get a quality product. Midwest Instrument is an industry leader in the design and manufacture of quality pulsation dampeners, offering a range of brass and stainless steel models to choose from.

Midwest Instrument is an industry leader in manufacturing and designing differential pressure gauges, transmitters, and switches. With over 60 years of experience, you can rest assured that we have all the skills, time, equipment, technology and workforce to get you the best products in the industry. Feel free to contact us to learn how our products can help you today!