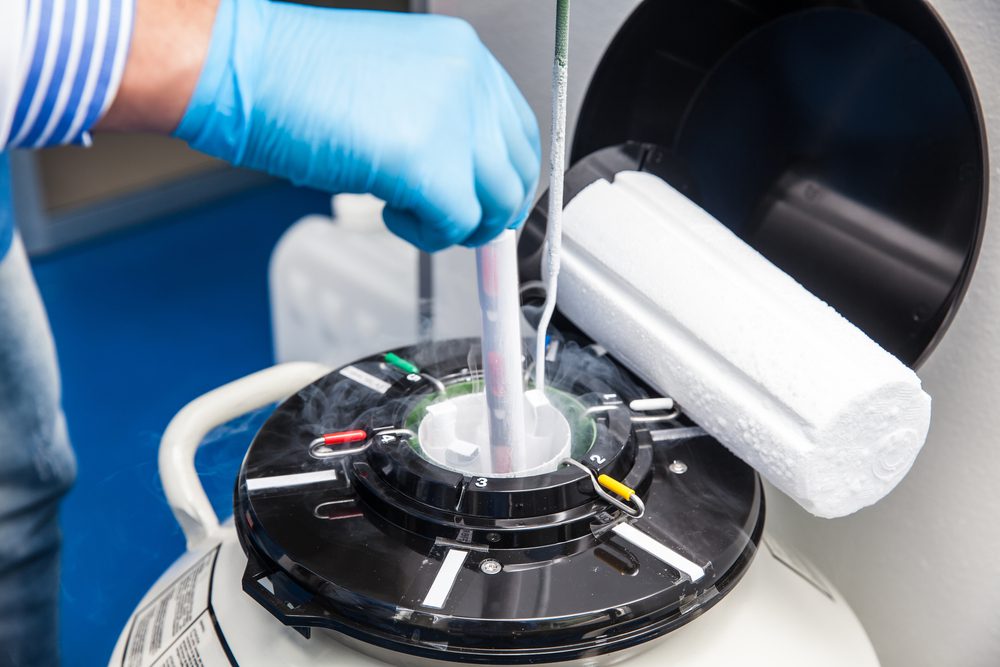

Cryotanks, also known as cryogenic tanks, are essential for storing and transporting substances at extremely low temperatures, typically below -150°C. These tanks are commonly used for the storage of liquefied gases, such as hydrogen, nitrogen, oxygen, and argon, as well as for the storage of biological samples and medical products that require low-temperature storage. This article will explain what cryotanks are, how they work, and the role of differential pressure gauges in cryotank operations.

What is a Cryotank?

Cryotanks are specialized storage vessels designed to maintain substances at cryogenic temperatures. They are made from materials that can withstand extreme low temperatures and are often double-walled with a vacuum between the walls to reduce heat transfer. Cryotanks come in various sizes, ranging from small portable units to large stationary tanks that can hold thousands of liters of liquid.

How does a Cryotank Work?

Cryotanks work by keeping substances at a temperature that is much lower than their boiling point. When substances are cooled to cryogenic temperatures, they become liquid and take up much less space than when they are in their gaseous form. Cryotanks store substances at low pressures to prevent them from boiling, and this is where differential pressure gauges come in.

The Role of Differential Pressure Gauges in Cryotank Operations

Differential pressure gauges are used to measure the height of the liquid in the tank. On a cryogenic tank the high pressure port of the DP gauge is piped to the bottom of the tank. Since the tank is pressurized, there will be pocket of gas above the liquid in the tank. The low port of the DP gauge will be piped to the air pocket at the top of the gauge. The DP gauge will measure the difference in pressure between the high and low ports providing an accurate reading of the liquid level in the tank.

In addition, differential pressure gauges can also help detect leaks in cryotanks. If there is a leak in a cryotank, the decrease in liquid level will be detected by the differential pressure gauge. This allows operators to take corrective action before the substance stored in the tank is compromised.

Conclusion

Cryotanks are essential for the storage and transportation of substances that require extremely low temperatures. They are used in a wide range of industries, including healthcare, biotechnology, and aerospace. Cryotanks work by keeping substances at a temperature that is much lower than their boiling point, and differential pressure gauges are used to measure the level of the liquid in the tank. The use of differential pressure gauges in cryotank operations is essential for the safe and efficient storage and transportation of cryogenic substances.

To Learn More About Pressure Monitoring

For over 60 years, Mid-West Instrument has been a leading provider of premium differential pressure gauges. Need help finding the right DP pressure gauge for your business? Reach out to us today to speak with one of our experienced professionals.