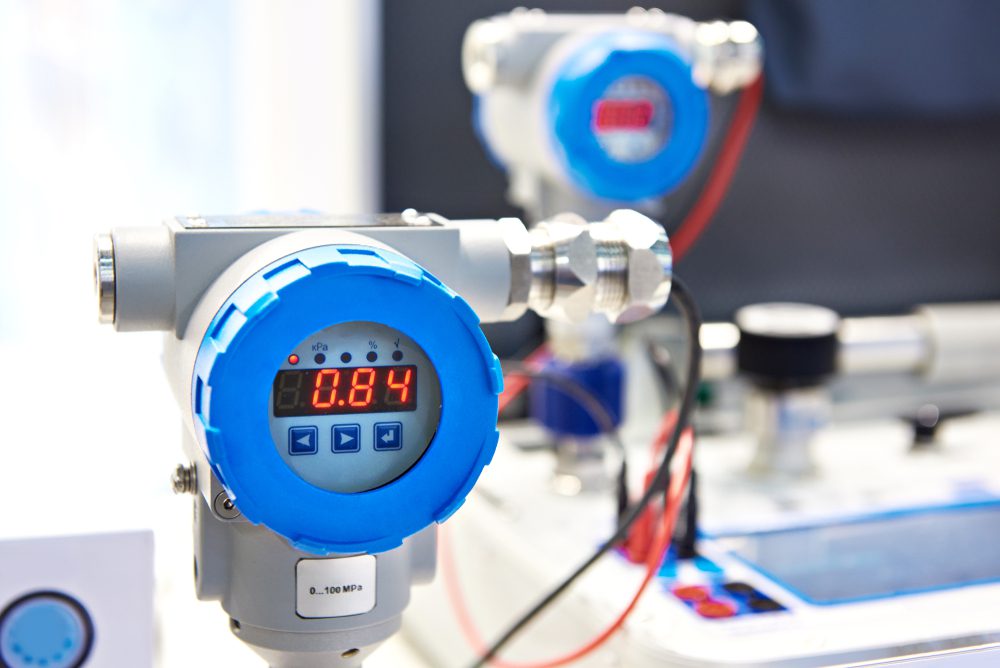

Digital differential pressure gauges are an essential tool for many industries, from HVAC systems to manufacturing processes. However, like any mechanical device, they are not infallible and can experience issues. Troubleshooting digital differential pressure gauge issues is crucial to ensure accurate readings and prevent costly downtime. In this article, we will discuss how to recognize common issues and how to prevent them.

Recognizing Issues in a Digital Differential Pressure Gauge

One of the most common issues with digital differential pressure gauges is inaccurate readings. This can be caused by a variety of factors, including calibration errors, clogged or dirty filters, or mechanical damage. It’s important to address inaccurate readings as soon as possible to prevent issues downstream in the system. If you notice discrepancies in readings, start by checking the calibration and adjusting it as necessary. If that does not resolve the issue, check for clogs or damage to the gauge or its components.

Another issue that can arise with digital differential pressure gauges is sensor drift. Over time, the sensors in the gauge can shift, leading to inaccurate readings. This is more likely to occur in gauges that are used frequently or exposed to harsh conditions. To prevent sensor drift, it’s important to perform regular maintenance on the gauge, including cleaning the sensors and checking for any damage.

Preventing Issues in a Digital Differential Pressure Gauge

Preventing issues with digital differential pressure gauges starts with proper installation and maintenance. When installing a new gauge, be sure to follow the manufacturer’s instructions carefully, ensuring that all components are securely in place. Regular maintenance is also crucial to prevent issues down the line. This includes cleaning the gauge and its components regularly, checking for damage, and calibrating the gauge as needed.

One of the most important steps in preventing issues with digital differential pressure gauges is to use them properly. Ensure that the gauge is used only within its specified parameters and that it is not subjected to harsh conditions or rough handling. Avoid exposing the gauge to extreme temperatures or humidity, as this can damage the sensors or cause other issues.

Conclusion

Digital differential pressure gauges are an important tool for many industries, but they can experience issues over time. Recognizing and addressing issues as soon as possible is crucial to prevent costly downtime or inaccurate readings. By following proper installation and maintenance procedures, as well as using the gauge within its specified parameters, you can prevent many issues from occurring in the first place. If you do experience issues with your digital differential pressure gauge, be sure to consult with the manufacturer’s instructions or seek the advice of a professional to ensure that it is properly repaired or replaced.

Mid-West Instrument

For over 60 years, Mid-West Instrument has been a leading provider of premium differential pressure gauges. Need help finding the right pressure DP gauge equipment for your business? Reach out to us today to speak with one of our experienced professionals.