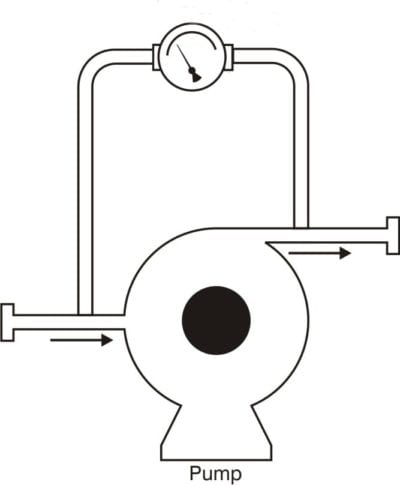

Pressure monitoring allows you to measure the status of gauge pressure. This allows you to protect your levels and increase the longevity if your equipment. A differential pressure gauge / switch / transmitter can help identify pump issues. Issues such as too high or low suction or discharge pressures can be caused by cavitation, loss of flow, mechanical failure, vibration, and bearing wear. While a switch can provide a warning for a defined pressure point, a 4-20ma transmitter in combination with a computer prediction algorithm can be used in pressure monitoring to identify an impending problem.

Pressure Monitoring with Different Types of Test Pressure Gauges

A test pressure gauge is a device or an industrial piece of equipment that is generally used to measure and visually indicate pressure or pressure fluctuations. It is critical that the test pressure gauge is accurate. To ensure that gauges work as intended, it is advised to calibrate the pressure gauges frequently. Testing, calibration, and validation are often conducted before as well as during any application.

Below we recommend two types of test pressure gauges, but if you’d like to know about the wide range test pressure gauges, visit our article here to learn more.

Pressure Monitoring with a Diaphragm or Piston type Instrument

A Diaphragm or Piston type differential pressure instrument can be used to monitor pump performance. The selection of a piston or diaphragm instrument will be dependent upon the process and particulates present in the process. If you’d like to know more information, please read our Piston vs Diaphragm article.