While Differential Pressure Gauges have been around for at least eighty years and their use may be “Old Hat” to many of you, it’s amazing how frequently this question is asked.

It usually comes up during a discussion about measuring the pressure drop across a filter or strainer and more often than not, is accompanied by the statement that “I use two pressure gauges, or one pressure gauge with a three way valve arrangement and measure differential that way.” Many times the comment is also made that either of these methods is cheaper than using a DP gauge. In most cases that isn’t true, however for the sake of this discussion let’s assume the installed costs are identical.

While cost is certainly an important consideration, most everyone will agree that it is the result you get from the expenditure that is of primary importance. Let’s pursue this comparison in a real life application and see why two pressure gauges or one with three-way valve, is virtually a complete waste of money compared to a differential pressure gauge in terms of results.

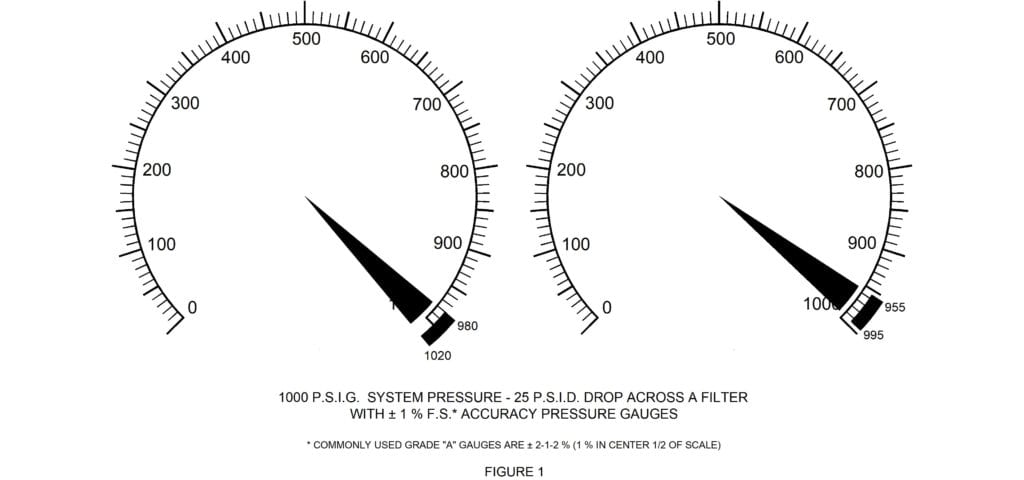

A not untypical application is a filter in a line flowing liquid at 1000 P.S.I.D. and with a filter element that will collapse if the differential pressure (the difference between upstream and downstream pressures across the filter) exceeds 25 P.S.I.D. Since the end result, errors, etc. are the same in either pressure gauge approach, let’s simplify this comparison by assuming two industrial quality 4 1/2” pressure gauges.

Figure 1. Shows the potential error if 1000 P.S.I.G. gauges are used and Figure 2. If 2000 P.S.I.G. are used. The maximum potential error is the same in either case since in fig. 1 you are reading in the + 2% region and in fig.2. in the + 1% error portion is 40 P.S.I.D. MORE than the collapse point of the filter element. While not germane to this discussion, perhaps it is also possible for these two gauges to erroneously indicate that flow is going in the reverse direction!

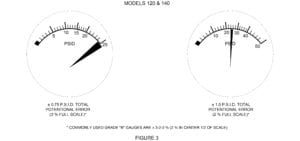

Figure 3. Demonstrates the error potential using a simple, inexpensive, differential pressure indicator. Even in the worst case, the 0-50 P.S.I.D. dial range, the total potential error is only 2 P.S.I.D. or 20 TIMES MORE ACCURACY than the two pressure gauges. To approach this kind of accuracy with pressure gauges would require an expenditure of at least $1500.00 for 2-1/10% F.S. accuracy gauges, compared to $100.00 or less for a simple DP gauge.

In addition to this huge advantage in accuracy, there are a number of other inherent advantages in using the differential pressure gauge.

- Substantially lower initial and installed cost.

- Far greater safety, since the typical low cost DP gauge is rated at anywhere from 3000 to 6000 P.S.I.G. (200 to 400 bar) and is far more safe than so called “solid Front” pressure gauges, since the system pressure is totally contained within the 3000 to 6000 P.S.I.G. bar stock body.

- The DP gauges are totally protected against overrange to the rated working pressure of the body.

- One or two switches may be added at a relatively low additional cost, to provide alarm and or control.