Differential Pressure Gauge and Switch Overview

“Bellows Type”

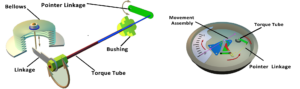

Differential pressure is applied to the bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly is mechanically coupled to the gauge indicator pointer. If equipped with a micro-switch, a cam mechanically linked to the bellows, rotates and triggers the micro-switch. The major components of the Model 105/106 are a two-piece body, bellows sensing element and over-pressure assembly, a torque tube assembly, a range spring and the gauge front assembly. Model 105/106 assembly is protected against over-range in either direction to the rated working pressure by a bi-directional relief valve.

• Uni-Directional & Bi-Directional Dial Scales Available

“Bourdon Tube Type”

Powered by a test quality Bourdon Tube Assembly which is encapsulated in a high pressure chamber that is fitted with a pressure connection to the inside of the Bourdon Tube and a second connection to the pressure chamber. The Model 109 indicates the difference between the pressure applied inside the Bourdon Tube and the pressure inside the chamber. The output shaft of the gauge assembly is magnetically coupled through the solid wall of the pressure chamber to a sensitive jeweled pointer shaft in the dial housing outside the chamber. The magnetic coupling transmits the exact motion of the assembly to the pointer to give an accurate dial reading of the differential pressure. The Bourdon Tube Assembly is protected against over-range in either direction to the rated working pressure by a bi-directional relief valve.

• Uni-Directional & Bi-Directional Dial Scales Available

“Switch Outputs”

Mid-West Instrument “High Accuracy” differential pressure gauges can be supplied with Micro Snap Acting Switches (80”-800” Bellows design only) or LOCKED-LOGIC SOLID STATE ALARM-CONTROL available for Bellows and Bourdon Tube Type Gauges to initiate alarms, activate other equipment, or initiate a system shutdown. Two switch units are also available for high and low alarms. Mid-West Instrument manufactures differential pressure gauges and switches to meet customer requirements.