There are a variety of gauge mount options for the installation of our differential pressure gauges. They can be mounted to panels, walls, pipes or with brackets. Frequently, safety, vibration, shock, or making the gauge visible and easy to read for the user requires taking the time to consider the different mounting configurations available.

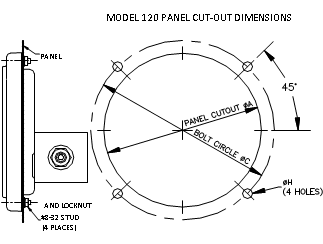

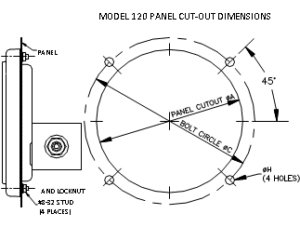

Panel mount

Many of our gauges can be mounted to a panel with a cut-out using the templates shown in our installation and operation manuals (IOM’s) and attached using either the bezel screws on the 2.5” dial chambered gauges to attach the gauge to the panel or with the provided studs & nuts to fit the body of our larger dialed gauges through the panel cut-out & securing the gauge with the nuts on the studs. Heavier gauges may need extra support when panel mounting.

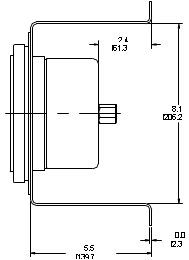

Wall mount

We have several options for mounting gauges to a wall or vertical flat surface. One option is a large sturdy bracket where the gauge is panel mounted and the bracket is mounted to the wall. Several other options mount a bracket to the gauge body and then the bracket is mounted to the wall.

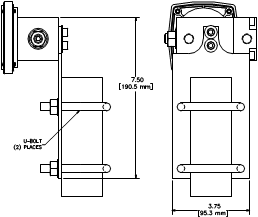

Pipe mount

We offer brackets for most of our gauges to mount to 2” vertical or horizontal piping.

These generally attach to the back of the gauge as shown.

Process piping mounting

When selecting a gauge mounting option consider that the process piping connecting the gauge to the system can sometimes be used to hold our smaller and lighter weight gauges in place. On most of our gauges the standard port option is ¼-inch FNPT process ports. The process piping and fittings that are normally attached to our gauges can be strong enough to hold our gauges in place. In those kinds of situations, extra mounting may not be required.

Special brackets

If there is a mounting challenge that can’t be met by one of our standard offerings please contact us to discuss designing a bracket or mounting to suit your application.