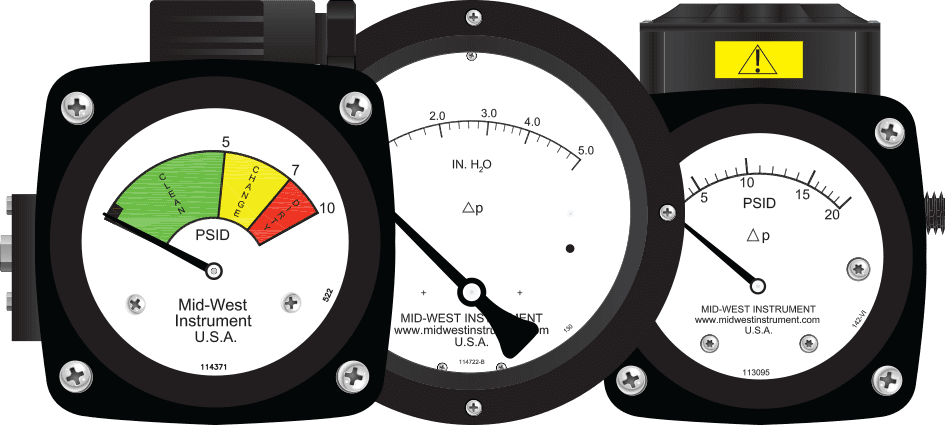

Diaphragm Gauge Description:

Mid-West® Instrument Diaphragm ΔP Gauges- Our diaphragm type gauge, the high and low-pressure ports are completely isolated from each other. There is no bypass and therefore they can be used for air, gas and liquids. They also come in a variety of dial scales allowing for very sensitive measurements. The Differential Pressure is sensed by the movement of an elastomer diaphragm against a precision calibrated range spring. The change in position of the diaphragm in response to the change in Differential Pressure moves an internal magnet. This magnet, in turn, causes a rotary magnet external to the gauge body to rotate and indicate ΔP on a dial.

Diaphragm-Type Differential Pressure Gauges are available with one or two hermetically sealed reed switches or a 4-20mA transmitter model dependent. The switches are adjustable within a defined percentage of the full scale range of the gauge and are available in SPDT and SPST normally open configurations for various load/power ratings. The switches can be set to activate or deactivate on rising or falling pressure. Models 130, 140, 142, 522, & 522A Switches are “CE” marked per the EU Low Voltage and RoHS Directives.

The Model 700 series uses a piezoresistive differential pressure sensor element. Silicone oil is filled between the die and 2 stainless steel diaphragms. The measured differential is amplified into a usable voltage or converted into a 4-20 ma output.

Hazardous location switches Models 140, and 142 are certified CSA and UL to Canadian & US Standards. Model 240 is CSA, UL Listed and CE marked to the ATEX directive and KOSHA certified along with the option for DPDT relays for higher load applications. The CSA & UL listings are for the entire assembly and not just the enclosure. See individual models for complete specifications.

OEM, Private Label, Special Dials:

Mid-West Instrument has the capability to design and engineer a Differential Pressure Gauge, Switch or Transmitter to the exact requirements of the customer. Dial size, Process connection Size and location, etc. can also be customized to the customer’s requirements. Mid-West has one of the fastest production times in the Industry. Our standard production time on most gauges is 7-10 business days or less.

Mid-West Instrument has the equipment and printing technology to provide color dials, flow scales and customer logo dials.

Please contact your Sales Coordinator for additional information and terms.