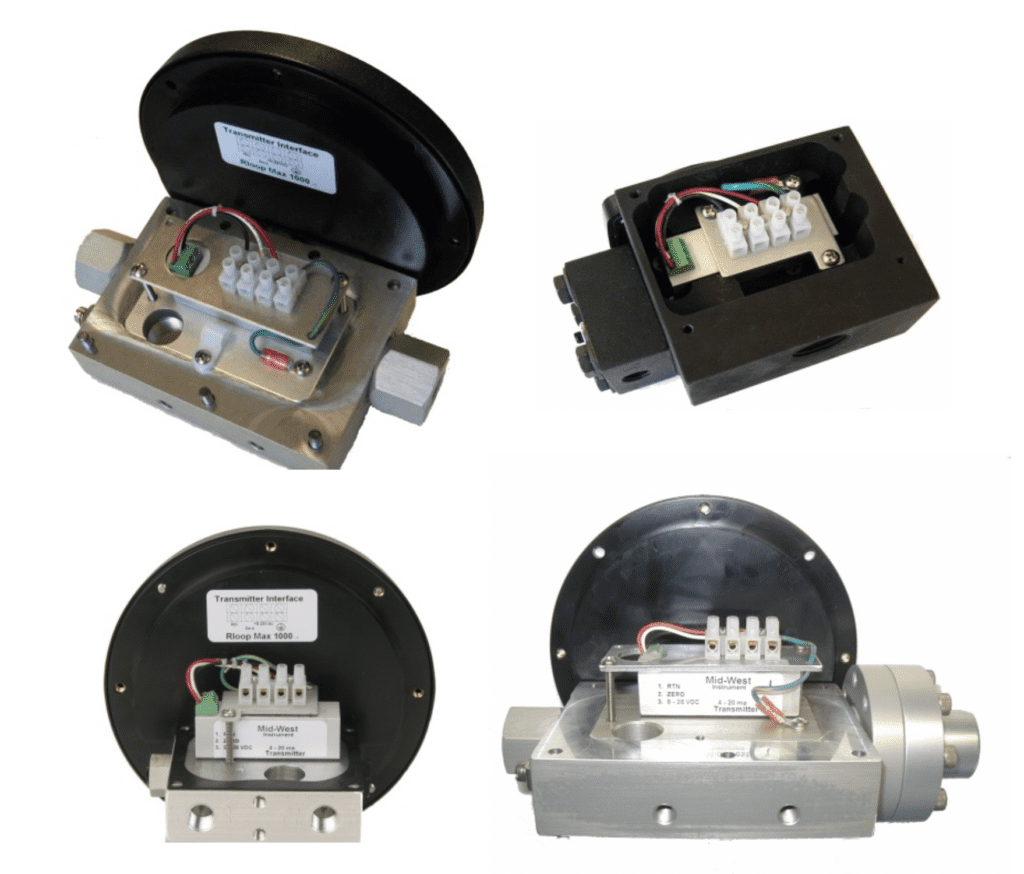

- 4-Position Terminal Strip

- Microprocesssor based technology

- External zero interface

- 8-28 vdc loop power

- 2 wire interface Diff

The purpose of a differential pressure transmitter is to measure and transmit the difference in pressure between two points in a system. This allows operators to monitor fluid or gas flow, level, or pressure across a variety of industrial applications, such as in HVAC systems, manufacturing processes, or oil and gas pipelines. Differential pressure transmitters convert the pressure readings into an electrical signal that can be transmitted to a control system or displayed on a gauge, providing accurate and reliable data for monitoring and control purposes. By using a differential pressure transmitter, an operator can maintain optimal performance, prevent downtime, and ensure the safety and efficiency of his processes.

Differential pressure transmitters can also help identify potential issues in a system, allowing for proactive maintenance and troubleshooting.