Diaphragm and Bellows type instruments are versatile choices suitable for serving as liquid tank level indicators, offering reliable measurements in various industrial applications. The mechanism is straightforward: the high-pressure port effectively links to a tap positioned at the tank’s bottom, while the low port is securely connected to the atmosphere, enabling accurate and efficient level sensing. This configuration ensures precise readings and provides valuable insights into liquid storage tank levels, facilitating proper monitoring and control of tank contents for optimal operations and enhanced safety.

How To Measure The Liquid Tank Level

A differential pressure instrument serves as a versatile and effective solution for measuring liquid levels based on the concept of head. One of the instrument’s notable advantages is its adaptability to accommodate various units of measurement, catering to the user’s specific requirements, whether in millimeters, inches of water, pounds, CO2, or other units, thereby enhancing its applicability across diverse industries.

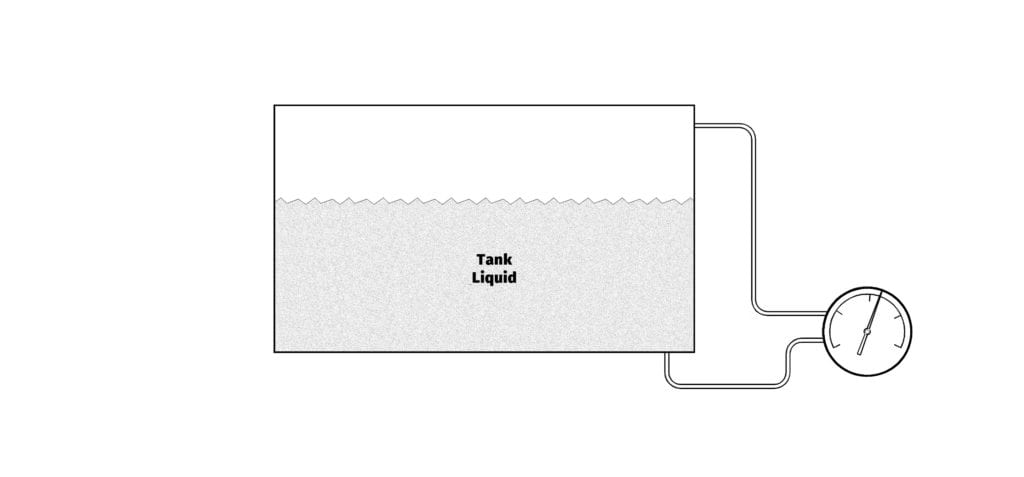

For open tanks, achieving accurate level measurements necessitates installing the differential pressure instrument at the bottom of the tank. This strategic placement ensures that the instrument gauges the liquid level precisely, considering the hydrostatic pressure exerted by the liquid column above it.

However, in scenarios where tanks are closed or subject to pressurization, a different approach is employed. Here, the low-pressure port of the differential pressure instrument can be thoughtfully connected to the top of the liquid storage tank, as illustrated in the accompanying figure. Despite the variation in pressure dynamics between open and closed tanks, the liquid inside will exhibit similar head characteristics. This means that the differential pressure instrument will continue to deliver reliable and accurate readings, ensuring a precise indication of the liquid level within the tank.

The flexibility and adaptability of the differential pressure instrument in handling diverse tank configurations underscore its importance as a valuable tool in industrial processes and applications where liquid level monitoring is critical. By providing users with a comprehensive and customizable solution, this instrument enables seamless integration into existing systems, optimizing efficiency, safety, and operational effectiveness across various industries and settings.

More Information

Watch this video by RealPars for a visual demonstration and Find a distributor to get the right instrument you need for liquid tank level measurement.