Differential pressure gauges play a pivotal role in various industrial applications, from monitoring HVAC systems to controlling filtration processes. Their accurate and reliable performance is critical for maintaining operational efficiency and safety. Calibration is the process by which the accuracy and reliability of differential pressure gauges are verified, adjusted, or corrected as needed. In this […]

Read More

The Calibration of Differential Pressure Gauges

December 15, 2023

Simplifying Filter Maintenance with Differential Pressure Indicators

August 10, 2023The differential pressure indicator is an invaluable device that plays a vital role in efficient filter maintenance and system performance. Designed to attach directly to filter canisters, these low-priced indicators are equipped with color-coded visual cues, making it easier to identify when it’s time to change the filter. In this article, we will delve into […]

Read More

Pressure Gauge Safety: Avoiding Common Hazards

July 30, 2023As vital tools in many industries, a pressure gauge will help monitor and manage the pressure levels of gases and liquids within containers or systems. They ensure the optimal operation of equipment, detect abnormalities, and prevent potential disasters. However, the improper use or handling of these gauges can lead to safety hazards, emphasizing the importance […]

Read More

Best Practices for Installing and Maintaining Pressure Differential Gauges

May 30, 2023Pressure differential gauges are critical components in many industrial applications, including HVAC, chemical processing, and oil and gas. These gauges measure the difference in pressure between two points in a system, providing valuable data for monitoring and control. However, to ensure accurate and reliable measurements, it is essential to install and maintain pressure differential gauges […]

Read More

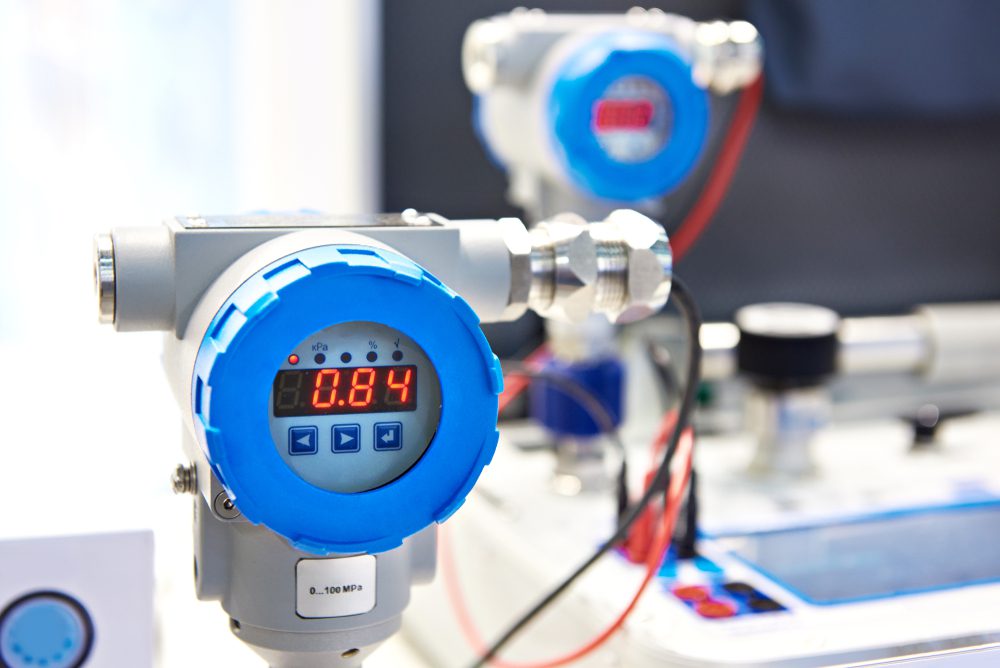

Troubleshooting Digital Differential Pressure Gauge Issues

April 30, 2023Digital differential pressure gauges are an essential tool for many industries, from HVAC systems to manufacturing processes. However, like any mechanical device, they are not infallible and can experience issues. Troubleshooting digital differential pressure gauge issues is crucial to ensure accurate readings and prevent costly downtime. In this article, we will discuss how to recognize […]

Read More

How Often Should Pressure Gauge Calibration Occur?

November 28, 2022Pressure gauge calibration is an essential part of maintenance to ensure the equipment works as intended and the readings remain accurate. If overlooked, it could lead to potential problems such as safety issues, penalties, and low-quality products. In this post, we will look at how pressure gauge calibration works and how often it should occur. […]

Read More

Steps for Selecting the Right Pressure Gauge

July 15, 2022Choosing a pressure gauge for your pressure measurement needs careful assessment of your needs. This includes the accuracy required, the type of application involved, the amount of pressure applied, and the size dial. Since it’s easy to get overwhelmed with choices if you’re not sure what you want, Mid-West Instrument, located in Sterling Heights, MI, […]

Read More

How Often Should I Check the Calibration of My Pressure Gauge?

June 10, 2022Calibration can be vital in ensuring your differential pressure gauge is able to give accurate readings. It refers to the process where the pressure gauge is tested against a reference calibration mark to ensure it’s working properly and reading accurately. With that in mind, how often should you check the calibration of your differential pressure […]

Read More

Reading Pressure Gauges on High-Vibration Applications

February 25, 2022On high-vibration industrial applications, reading a pressure gauge is often frustrating–and in some cases, downright impossible without the proper configuration on the gauge. An indicating needle that rapidly shakes back and forth makes it difficult to get an actual reading–especially so if the needle falls off its access because of the vibration. Damage to the […]

Read More