Whether your application is backflow prevention, reverse flow detection, or natural gas filtration in the Midwest, with high-quality gauges from Mid-West Instruments you’ll always know your flow. The following models are just a small sampling of what we have to offer.

Model 142

This diaphragm-type gauge provides a terminal strip interface to aid in the ease of electrical installation of your switch or transmitter. The Model 142 also has the option to add a 4-20 mA transmitter for applications that require constant monitoring. Full-scale accuracies of ±3/2/3% (0-20” H2O to 0-25 PSID) are available, as are multiple switch options (including hazardous location Class I Div. 2 options). The Model 142 is an accurate, versatile, low-cost diaphragm type differential pressure gauge/switch or transmitter that will meet your most demanding differential-pressure requirements.

Model 120

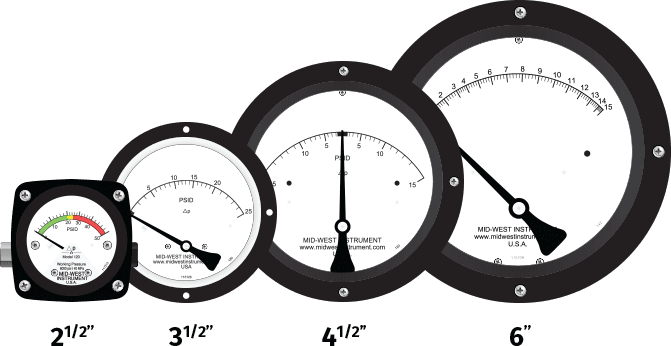

This piston-type gauge is our most versatile and customizable differential pressure gauge, designed to fit your most demanding requirements. Available with multiple switch options, including hazardous location options. With a full-scale accuracy of ±3/2/3% combined with differential pressure dial scales of 0-5 PSID to 0-110 PSID, this rugged design is ready to do the job wherever, whenever.

Model 122

Our most affordable entry-level piston gauge in the Midwest, with a full-scale accuracy of ±5% combined with differential pressure dial scales of 0-5 PSID to 0-110 PSID. Model 122 is available with clamp-on electrical switch options. Though it offers fewer options than other models in this line, the Model 122 promises a lower price point while still delivering exceptional performance.

Models 105, 106, 115 and 1116

For all of these models, the system pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly move to cause an electrical signal to be produced or to cause a gauge pointer to move. The major components are a two-piece body, bellows sensing element, and over-pressure assembly, along with a torque tube assembly, a range spring, and the gauge front assembly.

The body halves provide the pressure containment function and also clamp the sensing element and over-pressure assembly between the halves, isolating the high-side and low-side pressures of the system. The high-side body half also provides a mount for the torque tube assembly and the gauge front assembly. This assembly incorporates a bidirectional relief valve which provides over-pressure protection in both directions. When over-pressured from the high side, the valve is opened by a mechanical stop as the sensing element deflects to its maximum travel. When over-pressured from the low side, the spring-loaded valve opens when the differential pressure exceeds its maximum rating. The opening of the valve in either direction equalizes the pressure and protects the unit.

Models 845-5, 845-3, and 845-2

For the past 30 years, Mid-West Instrument has produced quality backflow test kits – and our Model 830 has been the benchmark of the industry for decades. Recently, our Models 845-5, 845-3, and 845-2 were added to both the FCCC & HR-USC and CA-NV AWWA list of acceptable gauges, joining Model 830.

After Model 830’s release, constant input from field testers led to refinements such as inline filters, laminated test procedures, and removable lids, as well as soft-seated needle valves and line pressure gauges. Further input testing and updated technology led to our portable Model 844, and subsequently to our newest product offering, the Model 845. This new model features all the benefits you’ve come to expect from our kits and is available in 5-valve, 3-valve, and 2-valve configurations. The addition of the Model 845 to our product lineup truly allows Mid-West Instruments to offer “A Test Kit for Every Preference”.

Differential pressure gauges serve many applications including filter monitoring, cryogenic tank level measurement, flow measurement, and portable test kits to ensure safe drinking water. To learn more about differential pressures gauges, contact the experts at Mid-West Instrument.