Natural gas is notable for being a fairly clean and pure form of energy. However, there will always be some small portion of condensed water, adulterants, contaminants, and other foreign objects in any transmission system–and when things go wrong, there may be a lot. These contaminants will tend to collect at the end of the system, where the user is burning the gas, and they will build up. Equipment damage and failure are the inevitable results if no corrective action is taken.

Methods of Natural Gas Filtration

All filters work on more or less the same principle. A fine mesh of some sort of sturdy material is placed where the liquid or gas to be filtered must pass through it. This filter will catch various contaminants according to its design and composition. Some filters are very simple, such as a steel mesh meant to separate large amounts of water from the natural gas flow. Some are far more complex, like microfiber glass coalescing systems that can clear the gas stream down to 20 parts per million. It is common to use multiple types of filters in conjunction with each other, as this increases the speed with which a substance can be filtered, vastly improves the quality of filtration, and allows the coarser filters to take the bulk of the large debris while leaving the finer and more expensive filters free to handle only more purified gas. As any filter will clog up over time, it is vastly more cost-efficient to let the larger filters do the brunt of the work. They are much easier to clean and replace, after all.

Natural Gas Filtration and Its Role in Long-Term Maintenance

Natural gas is a natural product of processes deep within the Earth, and different gas sources will have different compositions and will be mixed with other substances. This can include hydrocarbons, acidic gas, water vapor, and any number of other contaminants. Water condensation during travel and storage is also a serious issue. When the natural gas reaches its destination and is combusted by the end-user, these small amounts of contaminants will concentrate and build up over time. This is exactly how equipment gets clogged, dirty, and damaged. Filtration prevents this, multiplying the useful lifespan of equipment and maintaining proper function during this time.

Natural Gas Filtration and Its Role in Disasters, Accidents, and Other Unforeseen Events

Sometimes, despite our best intentions, things will go wrong. With natural gas, this can generally mean a leak, a failure, or, in very rare cases, an explosion. There are specific procedures for taking care of each of these eventualities, but what must be remembered is that natural gas is part of a vast national system. On some level, the majority of natural gas resources are plugged together. This means that a failure of integrity in one spot can lead to serious problems far down the line. This is precisely what filters are meant to protect against. Even if a leak lets water or other contaminants into the system, the filtration means that it will be automatically caught. If there is a catastrophic failure and large amounts of dirt, ash, carbon residue, and other pollutants are to enter the system, then again, the filter stands ready to catch them and prevent serious, expensive equipment failure. A filter is much cheaper to replace than a natural gas unit.

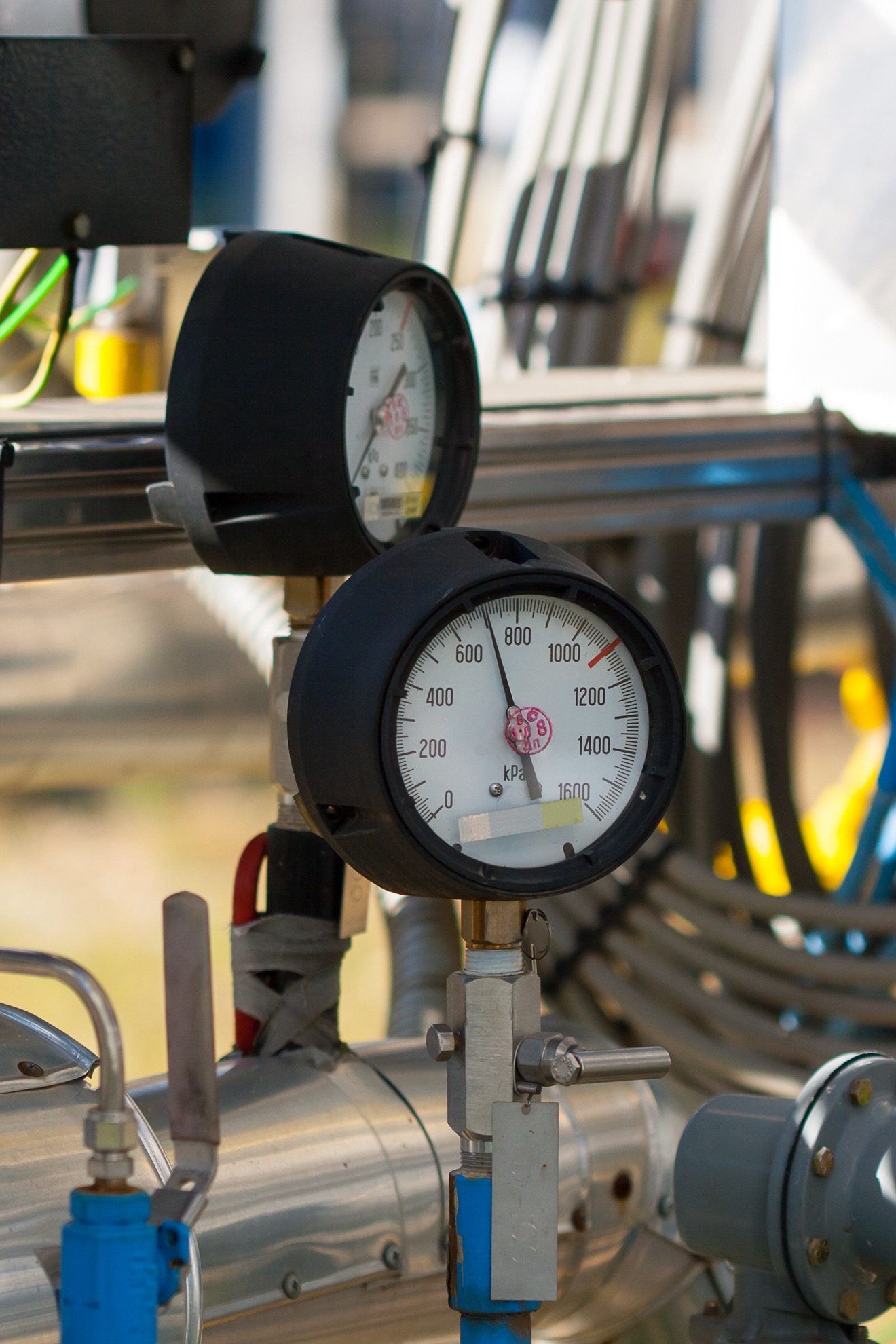

If you seek a quality differential pressure gauge manufacturer, Mid-West Instrument of Michigan designs and manufactures some of the finest differential pressure switches and gauges in America. – https://www.midwestinstrument.com/