Differential pressure gauges and pitot tubes are two essential instruments that come together in a dynamic partnership to measure fluid velocity in various applications. While pitot tubes detect the velocity of a fluid by measuring the pressure difference between its impact and static points, differential pressure gauges play a crucial role in interpreting and displaying this information. In this article, we will explore the intricate interaction between these devices and how they combine forces to provide accurate fluid velocity measurements. Additionally, we’ll highlight Mid-West Instrument‘s innovative solutions for optimal pitot tube applications.

Understanding the Pitot Tube and Its Velocity Measurement Principle

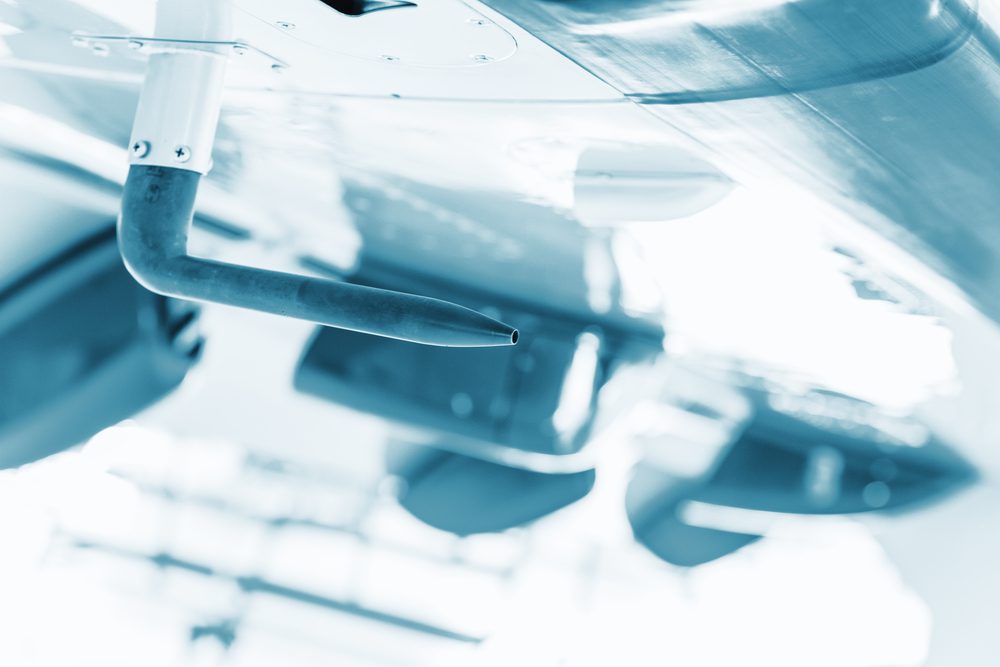

Pitot tubes are ingenious instruments that have been widely used for centuries in various industries, including aerospace, meteorology, and fluid dynamics research. The pitot tube consists of a slender, hollow tube with an opening at the front, facing directly into the fluid flow. This opening serves as the impact point, where the fluid’s dynamic pressure is exerted. Additionally, the pitot tube has one or more static pressure ports positioned on the side, perpendicular to the flow direction.

The velocity of the fluid is determined by measuring the pressure difference between the total pressure at the impact point and the static pressure at the side ports. This difference, known as the dynamic pressure, is directly proportional to the fluid’s velocity according to Bernoulli’s principle.

The Crucial Role of Differential Pressure Gauges with the Pitot Tube

While pitot tubes capture the dynamic pressure generated by fluid velocity, the raw pressure readings alone are insufficient to interpret the fluid’s actual velocity accurately. This is where differential pressure gauges step in as crucial partners in the process. These gauges are capable of measuring the difference in pressure between two distinct points in a fluid system.

In the case of pitot tubes, one of the pressure ports is connected to the impact point of the pitot tube, while the other pressure port is exposed to the surrounding static pressure. This connection enables the differential pressure gauge to determine the dynamic pressure by calculating the pressure difference between the impact and static points of the pitot tube.

Combining Forces for Accurate Fluid Velocity Measurement

By coupling pitot tubes with differential pressure gauges, the fluid’s velocity can be accurately and efficiently determined. As the fluid flows through the pitot tube, its dynamic pressure causes the differential pressure gauge to register a precise value based on the difference between the total and static pressures.

The resulting differential pressure reading is then used to calculate the fluid’s velocity using established formulas or calibration curves. This velocity measurement is invaluable in applications such as aircraft airspeed measurement, weather monitoring, and airflow analysis in HVAC systems.

Conclusion

The interaction between differential pressure gauges and pitot tubes is a fascinating example of how two essential instruments come together to provide accurate fluid velocity measurements. Pitot tubes capture the dynamic pressure of the fluid, while differential pressure gauges interpret this data to determine the fluid’s velocity. For top-notch solutions in pitot tube applications, trust Mid-West Instrument, a leading innovator in precision measurement technologies. With our advanced products, you can achieve optimal fluid velocity measurements and performance across diverse industries and applications.