Model 115

Bellows Type

Tank Level Gauge

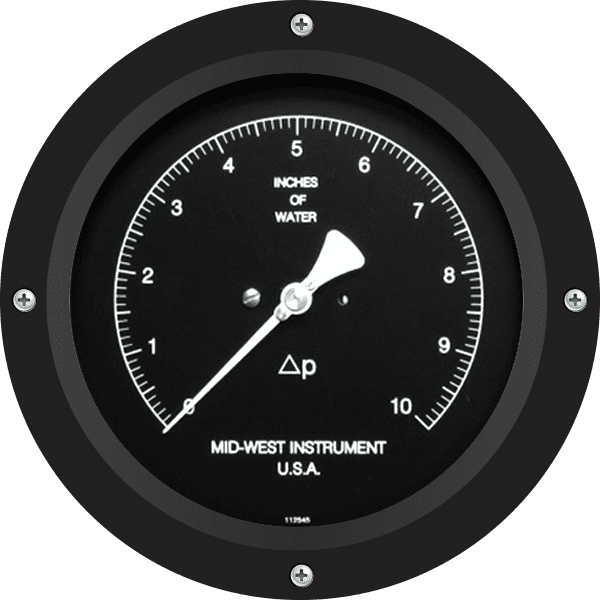

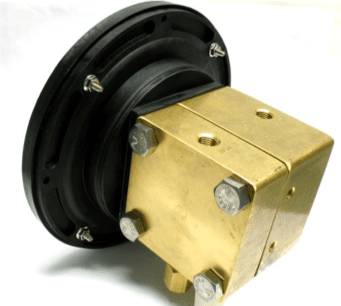

Mid-West® Instrument Model 115 Tank Level ΔP Gauge – ± 1% Full Scale Accuracy. System pressure is applied to the internal volume of a bellows and mechanical linkage assembly. As pressure changes, the bellows and linkage assembly is mechanically coupled to the gauge indicator pointer. The major components of the Model 115 are a two-piece body, bellows sensing element and over-pressure assembly, a torque tube assembly, a range spring and the gauge front assembly.

This assembly incorporates a bi-directional over-pressure relief valve (OPV) which provides protection in both directions. When the Differential Pressure exceeds 130% of the range the OPV equalizes the pressure between the Hi and Lo sides. ¼” FNPT Dual top and bottom connections are provided as standard. Model 115 Tank Level gauge is also equipped with a Micro adjust pointer. If necessary, the pointer can be re-zeroed. Body is made of brass with 316 Stainless Steel internals. Viton Seals are provided as standard. The Dial is 6” diameter with white lettering on a black dial. (White dial with black lettering optional) The 115 temperature limits are rated at -40° F to 200°F. Proof pressure is Two Times working pressure at ambient temperature.

Contact Us Today For AvailabilityProduct Features/Benefits

- Rugged Bellows Sensing Element

- Glass Reinforced Thermoplastic Dial case (Panel Mountable)

- Weather Resistant & Corrosion Resistant Gauge Front

- 270° Dial Arc

- Shatter Resistant Lens

- Over-Range Protection, High over Low and Low over High

- 1 Year Warranty

- For complete model details See Bulletin_115_116.pdf

- Installation and Operation Manual See Bulletin: IOM_115.pdf

Specifications / Configuration

- Dial Sizes available: 6” Diameters

- Dial Scale Ranges: 0-10” H2O to 0-69.9” H2O

- Differential Full Scale Ascending Accuracy available: ±1% (ASME B40.1 Grade 1A)

- Available in a Variety of Dial Scales: LOX, Ar, O2, N2, LBS. CO2, CM H2O, MM H2O, KGS, LNG, etc.

- Working Pressures 500 PSIG (34 Bar) 1000 PSI optional (69 Bar)

- Operating Temp -40°F to +200°F (-40°C to +93°C)

- Weather Protection & Corrosion Resistant

- Material of Construction of Body - Brass (Wetted Part)

- Internal wetted parts-316 Stainless Steel

- Dual Top and Bottom Process connections

- Brass Snubber fittings mounted in bottom process connections

- Optional O-rings Materials Buna-N, Viton, and Ethylene Propylene.

- For complete specifications see: Specificationsheet_115_116.pdf

Common Applications

- Pressurized Tank Level Monitoring

- Stationary Tanks – Horizontal or Vertical

- Tanker Transport / Over the road trailers For materials such as LOX, CO2, Ammonia, Nitrogen Helium, Nitrogen, Hydrogen and Argon

Additional Options:

- ¾” FNPT Stainless Steel Stub Mount Bracket

- Pipe Mounting Kit - 2" U-Bolt

- Multiple 3-Valve Manifold Options

- Oxygen Cleaning

- CRN – Canadian Registration Number

The Mid-West Advantage

- 1 year warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM and Private Label Capabilities

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System CSA B51-09 SAI GLOBAL

Model 115Documents

Tank Level , Diaphragm Type

| Model No. | Differential Pressure Range | Accuracy | Working Pressure | Electrical Available | Specifications | Installation/ Operation Manual | Electrical IOM | Drawing |

|---|---|---|---|---|---|---|---|---|

| Model 114 | 0-0.72 PSID (0-20" H20) to 0-20 PSID (0-600" H2O) Tank Level Applications |

±2% | 1000 PSI | CE / LVD, RoHS Compliant, NEMA 4X, 4-20mA Transmitter |

Tank Level , Bellows Type

| Model No. | Differential Pressure Range | Accuracy | Working Pressure | Electrical Available | Specifications | Installation/ Operation Manual | Electrical IOM | Drawing |

|---|---|---|---|---|---|---|---|---|

| Model 115 | 0-10" H2O to 0-69.9" H2O Tank Level Applications |

±1% | 500 PSI (Optional 1,000 PSI) | None available | N/A | |||

| Model 116 | 0-70" H2O to 0-800" H2O Tank Level Applications |

±1% | 500 PSI (Optional 1,000 PSI) | MICRO SWITCHES 0-80" H2O to 0-800" H2O NEMA 4X, CSA LISTED IND. CONT. EQUIP. |