Air filters play a critical role in maintaining indoor air quality and the efficiency of various HVAC systems. Whether it’s in your home, office, or industrial facility, clean and healthy air is essential. However, to ensure that your air filters are functioning optimally, you need a tool that provides real-time insights into their performance. This is where a differential pressure gauge for an air filter comes into play. In this article, we’ll explore the significance of these diaphragm type gauges, their operation, and how they contribute to better air quality. Additionally, we’ll introduce you to Mid-West Instrument’s reliable solutions for precise air filter monitoring.

Differential Pressure Gauge for Air Filter Overview

Differential pressure gauges, also known as DP gauges, are specifically designed to measure the pressure difference between two points in a system. When it comes to air filters, these gauges are invaluable because they help gauge the filter’s condition and overall efficiency.

How Differential Pressure Gauges Work

The operation of differential pressure gauges for air filters is relatively straightforward. They consist of two pressure ports: one connected before the air filter (the upstream side) and the other after the air filter (the downstream side). As air passes through the filter, dust, particles, and contaminants accumulate on its surface. This accumulation causes a restriction in airflow and subsequently results in a pressure drop across the filter.

Differential pressure gauges measure this pressure difference between the upstream and downstream sides of the filter. As the filter becomes clogged, this pressure differential increases, indicating that it’s time for maintenance or replacement. By regularly monitoring this pressure difference, you can ensure that your air filter operates at peak efficiency.

The Benefits of Using Differential Pressure Gauges

The advantages of using differential pressure gauges for air filters are significant:

- Improved Air Quality: By promptly detecting when a filter needs replacement, you can maintain a high level of air quality, free from dust and pollutants.

- Energy Efficiency: Clogged filters make your HVAC system work harder, increasing energy consumption and costs. Regular monitoring ensures your system operates efficiently.

- Cost Savings: Replacing filters only when necessary reduces filter replacement costs and minimizes unnecessary downtime.

Mid-West Instrument’s Solutions for Air Filter Monitoring

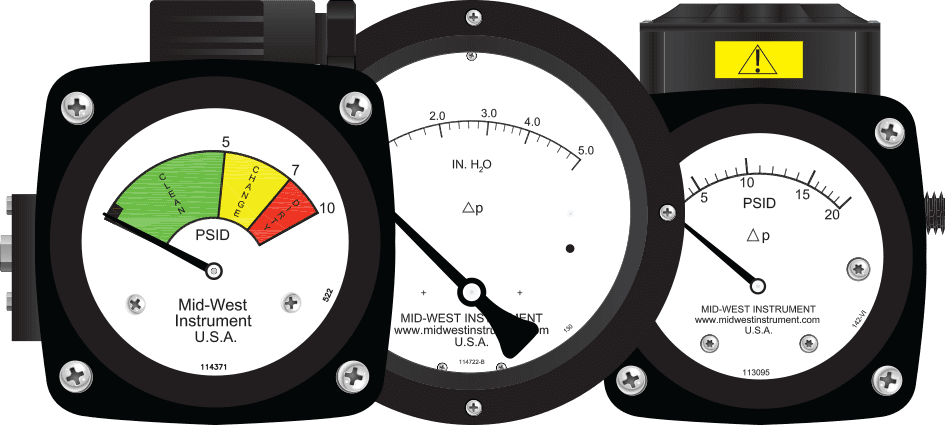

Mid-West Instrument offers a range of reliable and accurate differential pressure gauges designed for air filter applications. These gauges are known for their precision and durability, making them an ideal choice for various industries and environments.

Differential pressure gauges for air filters are indispensable tools for maintaining healthy indoor air quality and ensuring the efficiency of HVAC systems. By regularly monitoring pressure differentials, you can optimize filter replacement schedules, reduce energy consumption, and improve air quality. When it comes to reliable solutions for air filter monitoring, trust Mid-West Instrument to deliver precise and durable differential pressure gauges that keep your air clean and your systems efficient.

Midwest Instrument is an industry leader in manufacturing and designing differential pressure gauges, transmitters, and switches. With over 60 years of experience, you can rest assured that we have all the skills, time, equipment, technology and workforce to get you the best products in the industry. Contact us to learn how our products can help you today!