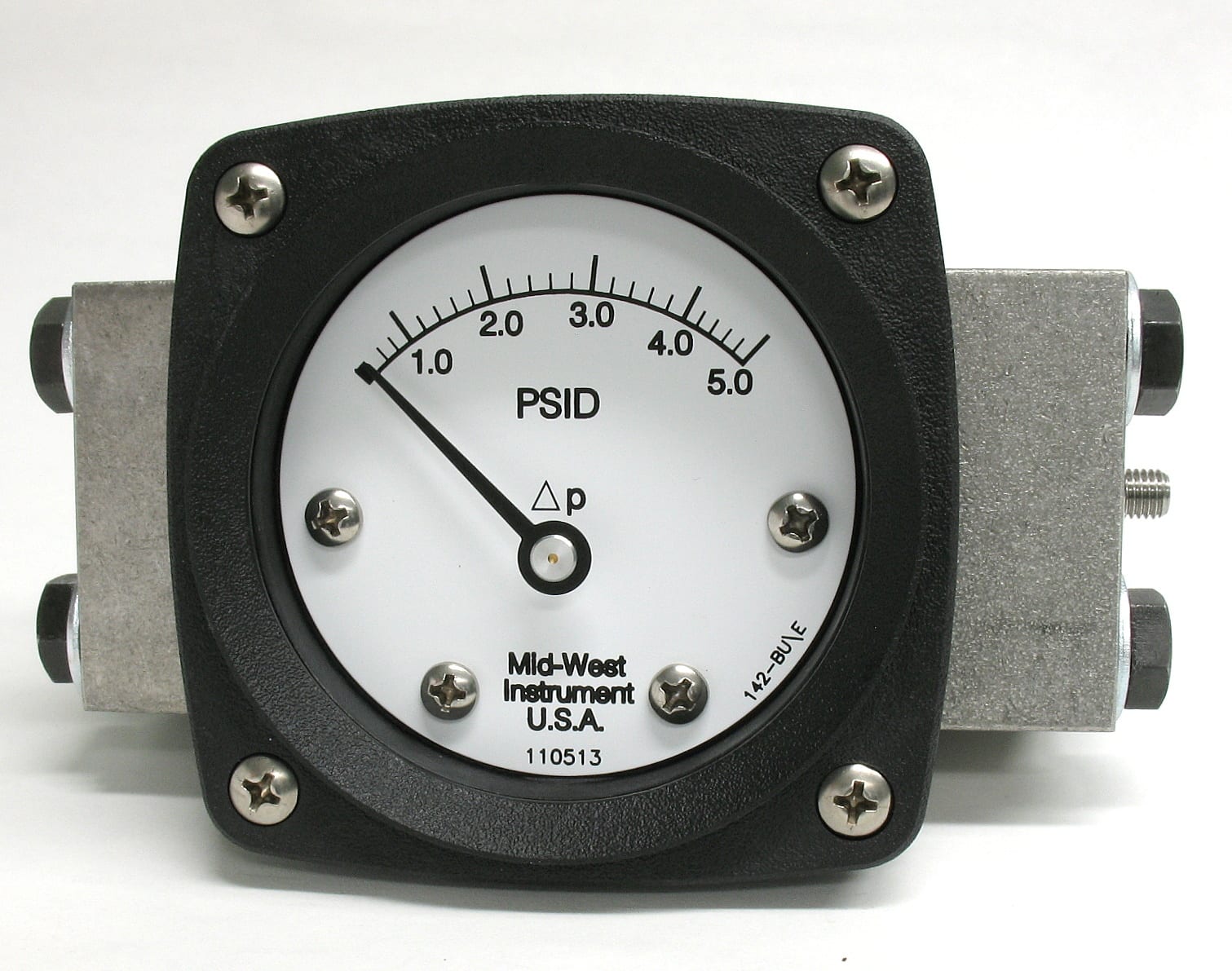

The Piston-type PSID (Pounds per Square Inch Differential) gauge is a precision instrument designed to measure the pressure difference between two points in a system. These reliable and rugged gauges find applications in a wide range of industries, from hydraulics and HVAC to filter and strainer monitoring. In this article, we’ll delve into the world of piston-type PSID gauges, exploring their functionality, applications, and the solutions offered by Mid-West Instrument.

The Mechanics of Piston-Type Gauges

At the heart of a piston-type PSID gauge lies a magnetic piston and a calibrated range spring encased within the gauge body. When pressure differentials occur between the high and low ports of the gauge, the piston responds by moving within the bore, acting against the range spring. This movement of the magnetic piston is precisely tracked by a rotary magnet located externally on the gauge’s body. As the magnetic piston shifts, the attached pointer on the dial indicates the pressure differential (DP).

Versatile Applications

Piston-type PSID gauges are engineered to excel in various demanding applications, including:

1. Filter and Strainer Monitoring: In fluid systems, it’s crucial to monitor pressure differentials across filters and strainers. Piston-type gauges offer accurate measurements to ensure efficient filtration processes.

2. Compressed Air Systems: Efficient operation of compressed air systems relies on maintaining precise pressure differentials. Piston-type PSID gauges assist in monitoring and controlling these systems.

3. Hydraulic Systems: Hydraulic machinery demands precise pressure control. These gauges play a pivotal role in ensuring hydraulic systems perform optimally.

4. Refrigerant Systems: In refrigeration applications, maintaining specific pressure differences is vital for efficient cooling. Piston-type PSID gauges help keep refrigerant systems in check.

5. Heat Exchanger Pressure Monitoring: Heat exchangers require consistent pressure monitoring to ensure heat transfer efficiency. These gauges help detect and address pressure drops.

6. Valve and Chiller Control: In valve and chiller systems, maintaining pressure differentials is critical for proper functioning. Piston-type gauges provide valuable insights for control.

Options for Precision and Functionality

Mid-West Instrument offers a range of piston-type PSID gauges with various specifications to meet diverse industry needs. These gauges can be equipped with one or two hermetically sealed reed switches or a 4-20mA transmitter, depending on the model. The adjustable switches provide flexibility within a defined percentage of the gauge’s full-scale range and come in SPDT and SPST configurations. These switches can be configured to activate or deactivate in response to rising or falling pressure, making them adaptable for different scenarios.

Ensuring Safety and Compliance

For hazardous environments, Mid-West Instrument provides certified models. Certain models are CSA and UL certified to Canadian and U.S. standards, while others are CE marked according to the ATEX directive and KOSHA certified. Additionally, options for DPDT relays are available for applications with higher load requirements.

Customized Solutions

Mid-West Instrument understands that every industry and application is unique. Therefore, they offer OEM, private label, and custom solutions. Whether you require specific dial sizes, customized process connections, or other tailored features, Mid-West Instrument can engineer a solution to meet your exact requirements.

Contact Mid-West Instrument Today

The Piston-type PSID gauge is an indispensable instrument across various industries where precise pressure differential measurements are essential. Mid-West Instrument stands as a reliable provider of these gauges, offering high-quality solutions tailored to your specific needs. Our commitment to precision, durability, and customization ensures that you have the right tools to monitor and control pressure differentials in your critical applications.