Teflon backup rings are crafted from Polytetrafluoroethylene (PTFE), a material celebrated for its exceptional chemical resistance, making it impervious to a vast array of chemicals, including acids, bases, and solvents. This quality ensures the Teflon backup ring is ideal for sealing applications involving corrosive fluids. The material’s resilience across a wide temperature spectrum, from -200°C to +260°C (-328°F to +500°F), equips it for use in extreme thermal conditions. Additionally, Teflon’s inherently low friction coefficient minimizes wear on the backup ring and the seal assembly, extending their operational lifespan.

Function and Benefits

The primary role of a Teflon backup ring in a pressure limiting valve is to prevent the extrusion and deformation of O-rings in high-pressure environments, where the risk of O-rings being squeezed into the clearance gap between mating surfaces is high. By offering rigid support, these backup rings enhance seal performance, ensuring a consistent and reliable seal under fluctuating pressures and temperatures, thus reducing the potential for leaks. Their resistance to chemicals and extreme temperatures makes them versatile components across various applications, from hydraulic systems to chemical processing equipment.

Design Considerations

Installing Teflon backup rings requires careful attention to avoid potential damage due to their comparative rigidity against more flexible materials like rubber. Ensuring proper sizing and placement is crucial for the effectiveness of the seal. It’s also important to consider the compatibility of the O-ring material with the fluids in the system to guarantee the durability of the seal. Depending on the application’s pressure direction and requirements, backup rings can be installed on one or both sides of an O-ring, and in some instances, multiple backup rings may be stacked for additional support.

Applications

Teflon backup rings find their utility in a broad spectrum of industries where durable and reliable sealing solutions are paramount. They are especially beneficial in hydraulic and pneumatic systems, enhancing seal performance in cylinders and valves. The oil and gas industry relies on them for sealing in drilling and production equipment, while their ability to withstand extreme pressures and temperatures makes them invaluable in aerospace applications. Furthermore, their resistance to aggressive chemicals ensures the integrity of seals within the chemical processing sector.

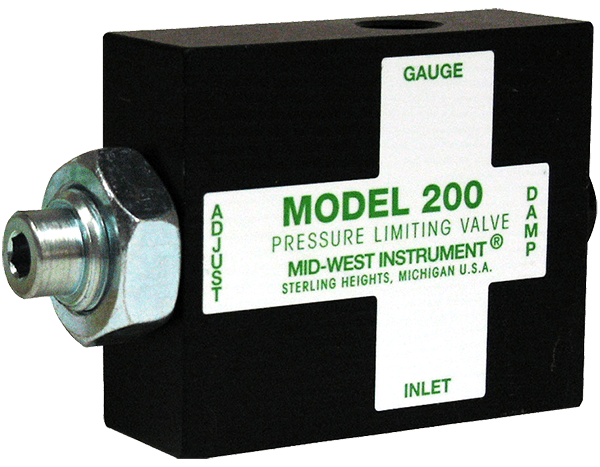

Mid-West Instrument

For over 60 years, Mid-West Instrument has been a leading provider of premium differential pressure gauges. Need help finding the right pressure gauge and equipment for your business? Reach out to us today to speak with one of our experienced professionals.