Differential pressure gauges are vital instruments in monitoring pressure differences in various industrial applications, such as filtration systems, flow measurement, and level monitoring in tanks. The bellows type differential pressure gauge is a specific design that utilizes a flexible, accordion-like component known as a bellows to measure pressure variations. Within this complex assembly, pressure gauge connection bushings play a critical yet often overlooked role in ensuring the gauge operates effectively and accurately.

Support and Alignment

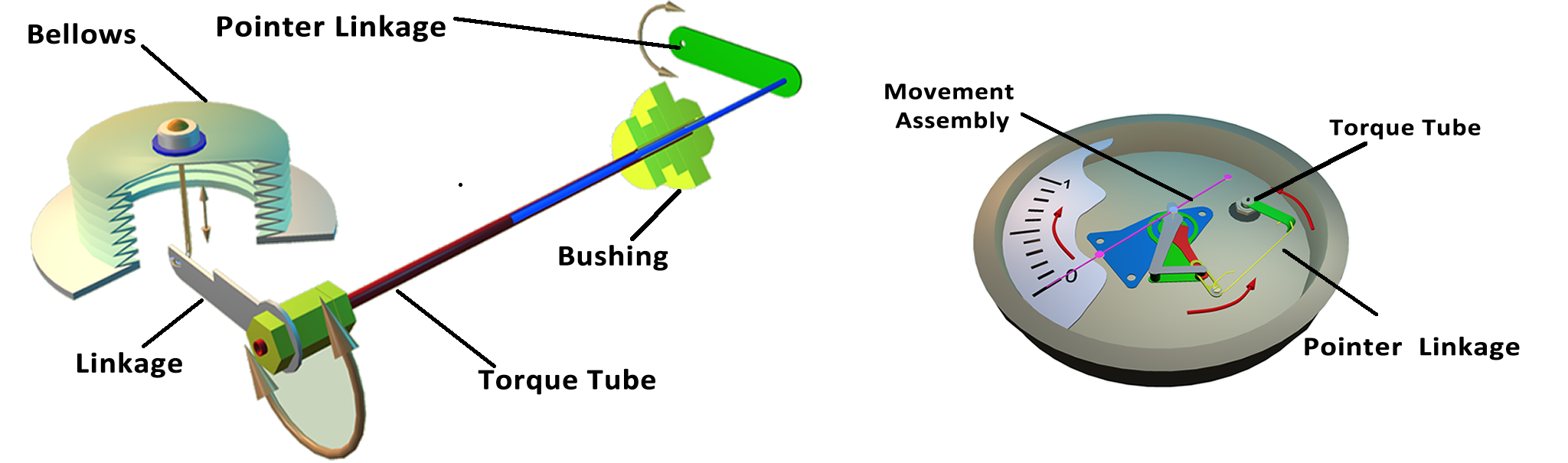

One of the primary functions of a bushing in a bellows type differential pressure gauge is to provide support and maintain the alignment of the moving components. The bellows, a key element of the gauge, expands and contracts based on the differential pressure across it. This movement is delicate and must be precisely guided to ensure accurate readings. The bushing serves as a stabilizing guide that keeps the bellows and connected mechanical linkages in proper alignment throughout their operational range. Without this support, the risk of misalignment is high, which could lead to inaccurate pressure readings and potentially costly errors in industrial processes.

Reducing Friction and Wear

In addition to providing structural support, bushings significantly reduce friction and wear within the gauge assembly. As the bellows expand and contract, various mechanical components move and interact. The bushing is strategically placed to create a smooth, low-friction interface between these moving parts. By reducing friction, the bushing not only enhances the responsiveness and sensitivity of the gauge but also extends the lifespan of both the bellows and the overall gauge assembly. This reduction in wear and tear is crucial for maintaining the integrity and reliability of the pressure measurement over time.

Enhancing Gauge Accuracy and Reliability

The accuracy and reliability of a bellows type differential pressure gauge heavily depend on the condition and performance of the bushing. A well-designed bushing ensures that the bellows can move freely and smoothly, which is essential for translating small pressure changes into accurate gauge readings. Furthermore, a bushing in good condition helps to prevent external contaminants and particles from interfering with the internal components of the gauge. By maintaining a clean and controlled environment inside the gauge, the bushing indirectly contributes to consistent, reliable, and accurate pressure measurements.

Longevity and Maintenance

The longevity of a bellows type differential pressure gauge can be significantly influenced by the quality and maintenance of its bushings. Regular inspections and timely replacement of worn or damaged bushings are critical maintenance practices that help avoid premature failures of the gauge. Since the bushing is subjected to continuous wear due to the mechanical movements within the gauge, understanding its condition and planning for its maintenance is essential. Implementing a routine maintenance schedule that includes checking the integrity and functionality of the bushing will ensure the gauge remains accurate and reliable for a longer period, reducing downtime and maintenance costs in industrial settings.

Conclusion

Pressure gauge connection bushings in a bellows type differential pressure gauge may seem like a minor component, but their role is pivotal in ensuring the gauge’s performance and durability. By providing crucial support, reducing friction, and enhancing the overall accuracy and reliability of the gauge, bushings help to optimize the functionality of differential pressure measurement systems. Understanding and maintaining these components is essential for any industry that relies on precise pressure monitoring to ensure safety, efficiency, and effectiveness in their operations. As such, the humble bushing deserves recognition for its significant contributions to the successful use of bellows type differential pressure gauges in various applications.

For over 60 years, Mid-West Instrument has been a leading provider of premium differential pressure gauges. Need help finding the right pressure gauge and equipment for your business? Reach out to us today to speak with one of our experienced professionals.