Elastomers are a vital category of polymers known for their remarkable elasticity, allowing them to return to their original shape after being stretched, twisted, or compressed. These materials are crucial in a variety of applications due to their unique properties, including flexibility, resilience, and resistance to wear and tear. In the realm of industrial instrumentation, elastomers play a pivotal role, particularly in the manufacturing and functionality of differential pressure gauges. This article will explore what an elastomer is and detail its specific use in a Mid-West Instrument differential pressure gauge.

Definition and Properties of an Elastomer

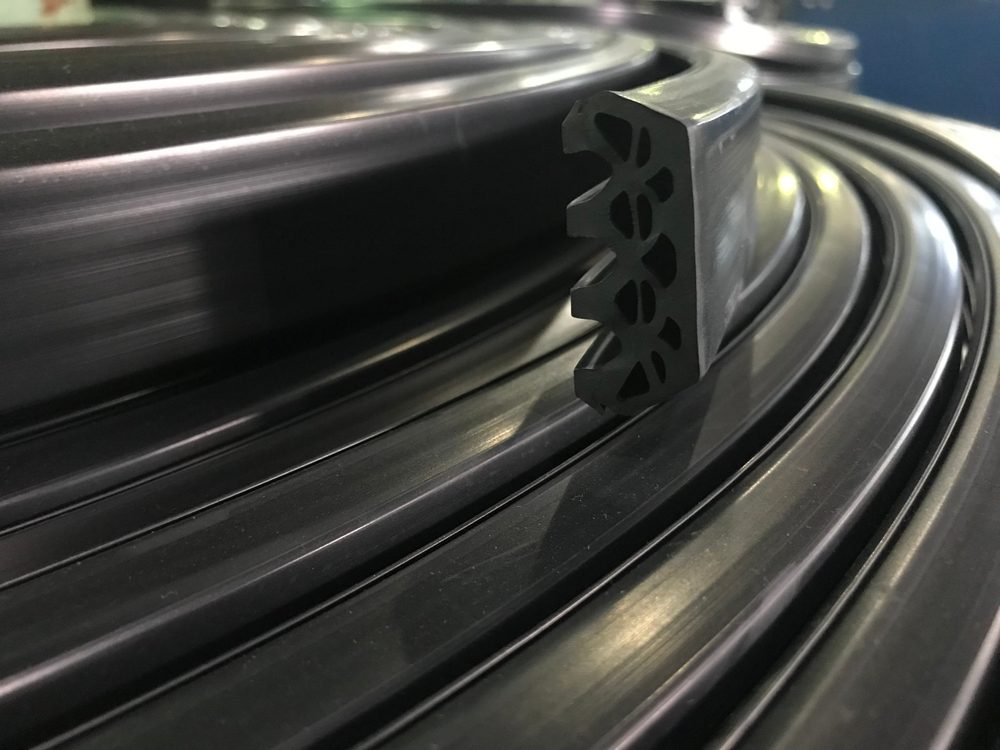

Elastomers are polymers with the property of viscoelasticity, commonly referred to as rubbery behavior. They have a molecular structure that allows them to be deformed under minimal force and return to their original state once the force is removed. Key characteristics of elastomers include high elongation, low modulus of elasticity, and the ability to absorb significant amounts of energy. These properties make elastomers ideal for sealing and cushioning applications because they can create tight seals and withstand repetitive stress without permanent deformation.

Elastomers in Differential Pressure Gauges

Mid-West Instrument utilizes elastomers extensively in their differential pressure gauges, primarily for sealing and protection purposes. In these devices, elastomers are found in the form of O-rings and gaskets, which are critical for maintaining the integrity and accuracy of the pressure measurement. These elastomeric components ensure that no external contaminants enter the system and no pressure medium leaks out, which is vital for reliable readings and the long-term durability of the gauges. The flexibility of elastomers allows them to conform to fine surface irregularities, providing an airtight seal even under fluctuating pressures and temperatures.

Applications and Benefits in Measurement Technology

The use of an elastomer in a differential pressure gauge presents several benefits:

- Enhanced Sealing Properties: Elastomers offer superior sealing capabilities, which is crucial for differential pressure gauges that operate under varying pressure conditions. Their ability to maintain a seal without degradation over time ensures that the gauges provide consistent and accurate measurements.

- Durability Under Dynamic Conditions: Differential pressure gauges often operate in environments where they are subjected to mechanical vibrations and thermal cycles. Elastomers are particularly valued in these settings for their ability to withstand such stressors without losing functionality.

- Chemical Resistance: Many elastomers used in Mid-West Instrument’s gauges are selected for their resistance to chemicals. This makes the gauges suitable for use with a wide range of fluids, including corrosive substances, without the risk of the elastomeric parts degrading.

Conclusion: The Role of Elastomers in Advancing Instrumentation

Elastomers are indispensable in the design and function of Mid-West Instrument’s differential pressure gauges. Their exceptional sealing properties, coupled with their resilience and chemical resistance, make them ideal for ensuring the reliability and accuracy of these critical measurement tools. As material science advances, the properties of elastomers continue to improve, further enhancing the performance of differential pressure gauges. Understanding the role of elastomers not only highlights their importance in specific applications like pressure measurement but also underscores their broader significance in modern industrial technologies. This integration of elastomers into critical measurement tools demonstrates how material innovation directly contributes to the advancement and reliability of industrial instrumentation.

For over 60 years, Mid-West Instrument has been a leading provider of premium differential pressure gauges. Need help finding the right pressure gauge and equipment for your business? Reach out to us today to speak with one of our experienced professionals.