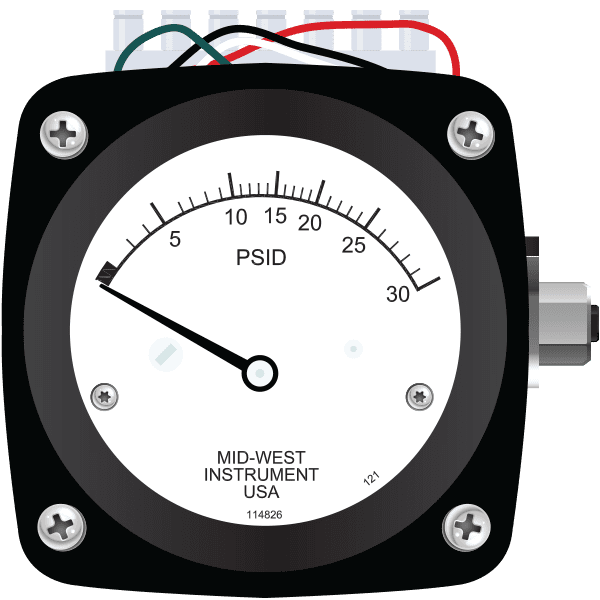

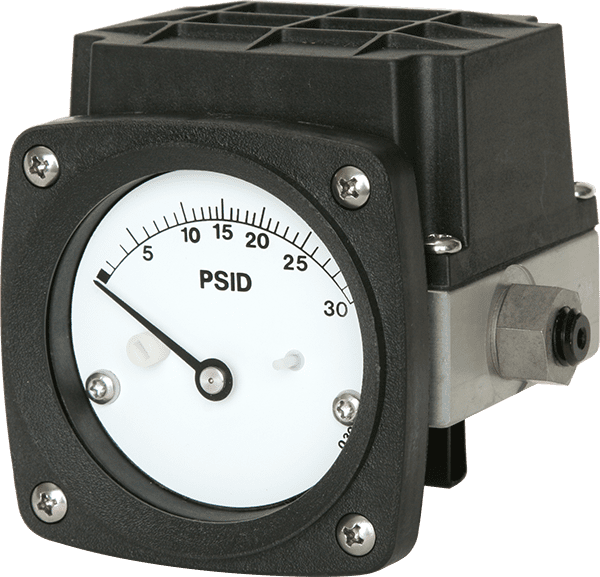

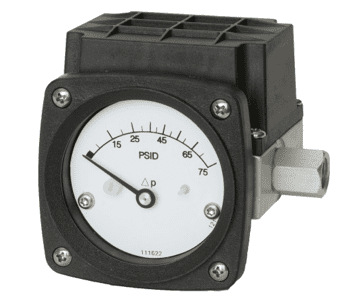

Model 121

Piston Type Gauges

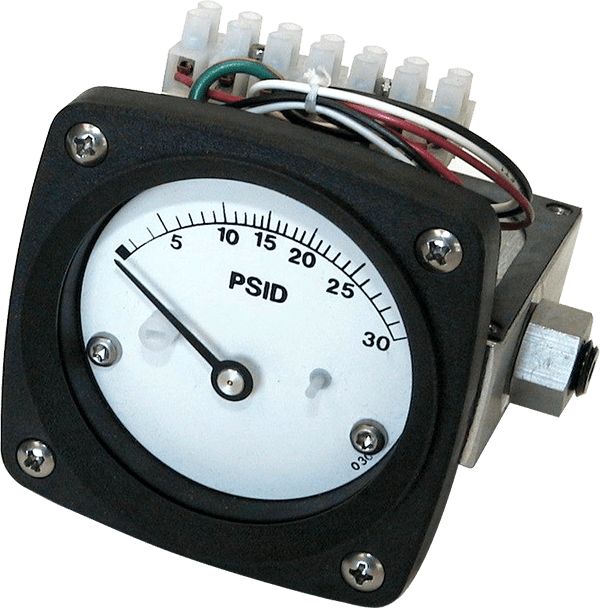

Model 121 –Is provided with a terminal strip interface to aid in ease of electrical installation of your switch or transmitter . The Model 121 also has the option to add a 4-20 mA transmitter for applications that require constant remote monitoring. With a Full scale accuracy of ±3/2/3% combined with Differential pressure dial scales of 0-5 PSID to 0-100 PSID, the Model 121 is an accurate and versatile differential pressure switch for your most demanding DP requirements.

Contact Us Today For AvailabilityProduct Features/Benefits

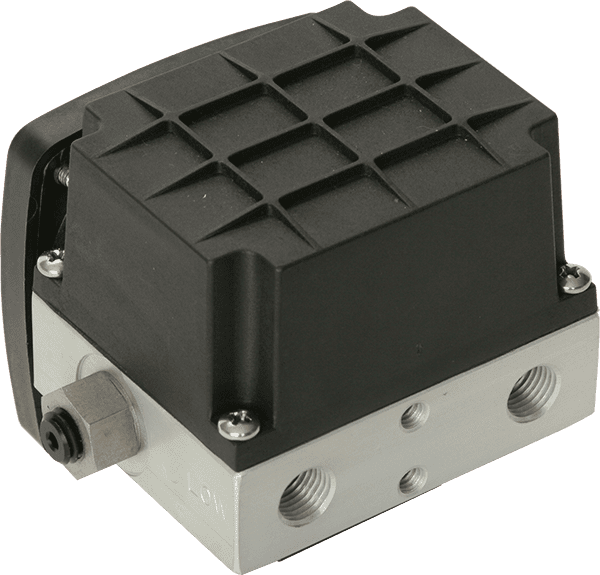

- Rugged Piston Type Design Sensing Element

- Glass Reinforced Thermoplastic Dial case (Panel Mountable)(Anodized Aluminum Dial Case Option available contact sales for more information)

- Weather Resistant & Corrosion Resistant

- Shatter Resistant Lens

- Over-Range Protection, High over Low and Low over High

- Switch & Transmitter options with Terminal Strip Interface

- 5 Year Warranty

- For complete model details See Bulletin_121.pdf

Specifications / Configuration

- Dial Sizes available: 2-1/2”, 3-1/2”, 4-1/2” and 6” Diameters (Uni-Directional & Bi-Directional)

- Differential Full Scale Ascending Accuracy ±3/2/3% (ASME B40.1 Grade B)

- Dial Scale Ranges: 0-5 PSID to 0-100 PSID (0-0.35 to 0-7.0 bar)

- Available in a Variety of Dial Scales: Bar, Mbar, kPa, Kg/Cm2, Dual Scale etc.

- Working Pressures up to 6000 PSIG (400 Bar)

- Operating Temp -40°F to +200°F (-40°C to +93°C)

- Weather Protection NEMA 4X/IP65

- ¼-20 Mounting Holes in back of gauge body

- Material of Construction of Body - Aluminum, 316/316L Stainless Steel (Wetted Part)

- Internal wetted parts-316 Stainless Steel, Ceramic

- Multiple instrument process connection size and locations available

- O-rings Materials: Buna-N, Viton, Neoprene, Teflon, Ethylene Propylene (Perfluoroelastomer optional)

- For complete specifications see: Specificationsheet_121.pdf

Common Applications

- Filter and Strainer monitoring

- Compressed Air

- Hydraulic

- Refrigerant

- Pump Performance Testing

- Heat Exchanger pressure drop Monitoring

- Valves, Chillers etc.. and flor local flow indication and control

Switch Electrical Specifications:

See Installation and Operation Manual IM121elec

Mid-West Instrument switches are mechanically adjustable allowing customer to set the switch within a defined adjustment span of range of the instrument. All configurations have a ½” FNPT conduit interface. Mid-West can also pre-set switch set point(s) upon customer request. All Switches are CE marked per EU Low Voltage and RoHS Directive.

Mid-West Instrument 121 indicating / non-indicating differential pressure transmitter is a 2 wire loop powered microprocessor based 4-20 mA transmitter. The magnetic angle sensor & electronics senses the angle (relative to the transmitter sensor) of the magnet which moves linearly in the bore. Each transmitter is individually calibrated to the gauge using an 11 point calibration linearization technique. Transmitter options can be CE marked for RoHS and EMC Directive upon request.

- No Power required to operate switches

- 1-2 Independent adjustable Switches

- 4-20 ma Transmitter (8-28 VDC Loop Power) 2% Accuracy (20%-100% of scale, Ascending)

- Numerous available switch output options

- SPDT 3W, 0.25 Amp, 125 VAC/VDC

- SPST 60W, 3.0 Amp, 240 VAC/VDC (Normally Open)

- SPST 60W, 3.0 Amp, 240 VAC/VDC (Normally Closed)

- SPST 60W, 3.0 Amp, 240 VAC/VDC (1 Normally Open, 1 Normally Closed)

- Field Wireable Terminal Strip

- Switch Options CE marked to Low Voltage and RoHS Directives

- Electrical Enclosures Weather-Resistant, NEMA 4X

- Hazardous Locations Options

-

- Class I Division 2, Groups A, B, C, D; Class II, Division 2 Groups F & G

- Transmitter & Switch Options

- Complete assembly 3rd Party Certified

Additional Options:

- Pipe Mounting Kit - 2" U-Bolt

- Wall Mounting - Rear Mount

- Liquid Fill

- Oxygen Cleaning

- Maximum Follower Pointer

- NACE Compliance

- CRN – Canadian Registration Number

The Mid-West Advantage

- 5 year warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM and Private Label Capabilities

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System CSA B51-09 SAI GLOBAL

- UL Listing

- CSA Listing

“Piston Type” Gauges with Electrical Optional

| Model No. | Differential Pressure Range | Accuracy | Working Pressure | Electrical Available | Specifications | Installation/ Operation Manual | Electrical IOM | Drawing |

|---|---|---|---|---|---|---|---|---|

| Model 120 | 0-5 PSID to 0-110 PSID | ±3/2/3% | Up to 6,000 PSI | CE / LVD, RoHS Compliant, NEMA 4X, Flying Leads / DIN Connector, Class 1-Div. 1, Class 1-Div. 2 | ||||

| Model 122 | 0-5 PSID to 0-110 PSID | ±5% | 3,000 PSI | CE / LVD, RoHS Compliant | ||||

| Model 123 | 0-150 PSID to 0-400 PSID | ±3/2/3% | Up to 4,000 PSI | CE / LVD, RoHS Compliant, NEMA 4X, Flying Leads / DIN Connector, Class 1-Div. 2 | ||||

| Model 124 | 0-5 PSID to 0-110 PSID and 0-150 PSID to 0-400 PSID |

±3/2/3% | 10,000 PSI | CE / LVD, RoHS Compliant, NEMA 4X, 4-20mA Transmitter |

Electrical “Piston Type” Gauges

| Model No. | Differential Pressure Range | Accuracy | Working Pressure | Electrical Available | Specifications | Installation/ Operation Manual | Electrical IOM | Drawing |

|---|---|---|---|---|---|---|---|---|

| Model 121 | 0-5 PSID to 0-100 PSID | ±3/2/3% | Up to 6,000 PSI | CE / LVD, RoHS Compliant, NEMA 4X,Terminal Strip, Class 1-Div. 2, 4-20mA Transmitter | N/A | |||

| Model 220 | 0-5 PSID to 0-100 PSID | ±3/2/3% | Up to 4,000 PSI | CE / ATEX / RoHS Compliant, KOSHA CERTIFIED, NEMA 4X, Terminal Strip, Class 1-Div. 1, Class 1-Div. 2, 4-20mA Transmitter | N/A |