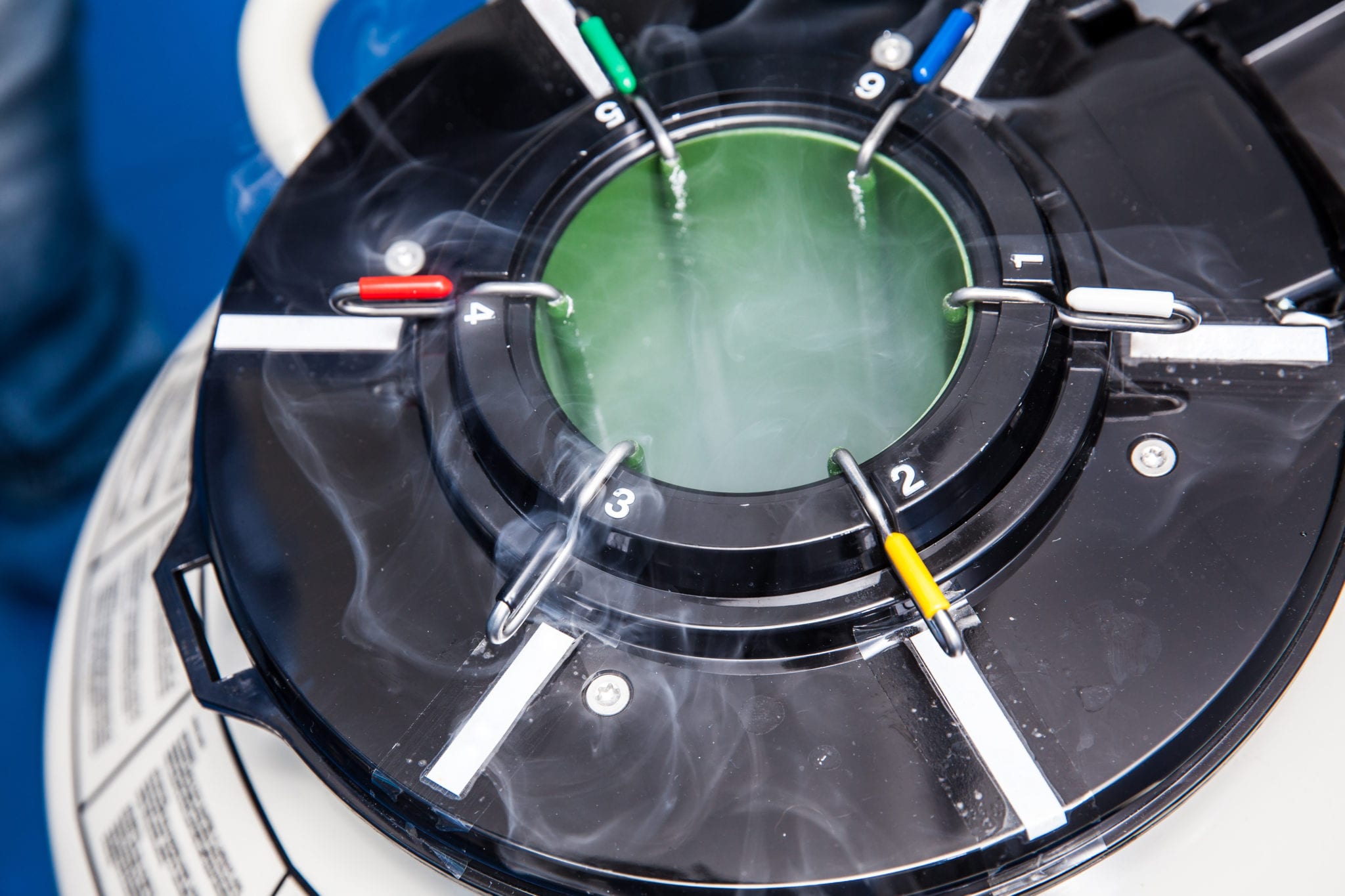

While the storage of food or standard liquids is generally not a complex topic, there are times where special equipment and environmental factors become critical. In cases where compounds like argon, helium, and liquid nitrogen are stored, lower temperatures with special conditions are needed. This is where a cryogenic tank becomes a useful piece of equipment.

When using a cryogenic tank, the user should have a thorough understanding of how the system works. This includes the ability to read the level indicators that are part of the tank. We take a look at how the level indicators work and why they are present on cryogenic tanks.

What Is The Role Of The Level Indicator?

A cryogenic tank contains multiple sensors on the interior. These sensors play an important role in detecting the amount of fluids that are present within the tank itself. The level indicator is located on the control panel of the cryogenic tank – and the sensors connect to this particular part of the tank.

Certain compounds need a specific amount of fluids to be available in the tank at all times. Should the tank run dry, complications could develop with the compounds stored inside the container. Thus, the level indicator provides an overview of the fluid level. It essentially serves as an indication of when the tank needs to be filled with the appropriate fluids again.

Some of the more modern models may also come with an automatic or “smart” function. In this case, a computerized module is connected to the level indicator. This module automatically detects the fluid level at all times. While monitoring, the system would automatically add more fluids to the tank as needed.

The Most Common Types Of Level Indicators

While the function remains the same, there are different types of level indicators on the market. Be sure to understand the difference and purpose of every indicator type. This allows you to find the option that is most suitable for your specific needs.

Swimming pool indicators, for example, are used in both commercial and residential pools. These indicators give you a view of the current water level and tell you when to fill up the pool again. They can also be connected to a smart system for automatic water level maintenance.

In industrial applications, a relatively large variety of sensor options can be used in level indicators – such as the following::

- Optical sensors

- Tuning forks

- Vibrating forks

- Floats

- Radar sensors

- Resistance sensors

- Conductivity sensors

- Capacitance sensors

The specific use for each differs – but they all focus on monitoring a specific element. Apart from compounds in a cryogenic tank, level indicators are sometimes used for purposes in other industries too – such as to provide an indication of electricity running through a system.

Cryogenic tank level indicators are known to be compact yet very useful. They are essential when it comes to the maintenance of cryogenic tanks and make the process of monitoring fluid levels significantly easier.

Conclusion

Level indicators on a cryogenic tank should be consistently monitored. These indicators provide a reading on the current fluids inside the container. Understanding how to read these indicators can provide more efficient storage and avoid potential complications when storing compounds under very specific conditions.