When it comes to measuring differential pressure (DP), selecting the right gauge is crucial. The choice depends on your specific application and requirements. In this guide, we’ll compare different types of differential pressure gauges, their features, and ideal applications to help you make an informed decision. Whether you need to monitor filter efficiency, control flow rates, or ensure the safety of your systems, Mid-West Instrument has a solution for you. You’ll find a summary of different types below, but check out our Selection Guide for full details.

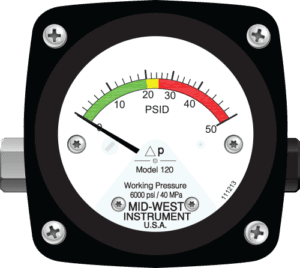

Piston Type Gauge

Accuracy: ± 2% or ± 5% Full Scale Accuracy.

Piston-type differential pressure gauges are primarily designed for liquid applications. They use a precisely ground floating piston/magnet to sense differential pressure. The magnet’s movement in response to pressure changes is translated into a dial reading by a rotary magnet external to the gauge body. These gauges exhibit a slight amount of bypass for fluids, making them less suitable for gas applications.

Ideal for: Liquid applications where precision measurement is critical.

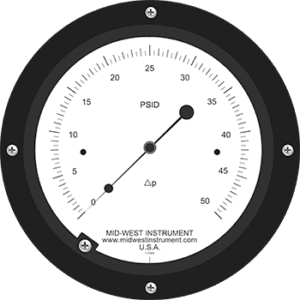

Diaphragm Type Gauge

Accuracy: ± 2% or ± 5% Full Scale Accuracy.

Diaphragm-type differential pressure gauges are highly versatile. The high and low-pressure ports are completely isolated from each other, making them ideal for dissimilar fluids, air, gases, or liquids with a high concentration of solids. They offer precise measurements and come in various sizes.

Ideal for: Applications with dissimilar fluids, air, gases, or solids-laden liquids.

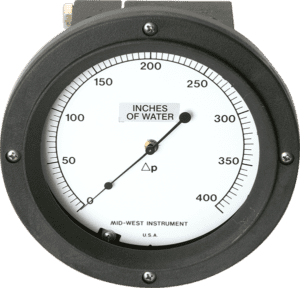

Bellows Type Gauge

Accuracy: ± 1/2% or ± 1% Full Scale Accuracy.

Bellows-type differential pressure gauges use a bellows and mechanical linkage assembly to measure pressure changes. They are highly accurate and equipped with a cam-triggered micro-switch for certain models. These gauges are protected against over-pressure in both directions.

Ideal for: Applications demanding high accuracy and over-pressure protection.

Bourdon Tube Type Gauge

Accuracy: ± 1/2% or ± 1% Full Scale Accuracy.

Bourdon Tube-type differential pressure gauges rely on the deformation of a flattened tube when pressure is applied. They offer quick response times, making them suitable for leak detection and applications where isolation diaphragms are required.

Ideal for: Applications requiring rapid response and low volume displacement.

Mid-West Instrument

Each type of differential pressure gauge has its unique advantages and ideal use cases. When choosing the right one, consider your specific application, required accuracy, and environmental factors. Remember that Mid-West Instrument offers a wide range of solutions, and our team can help you find the perfect DP gauge for your needs.

For Filter Monitoring, HVAC Systems, Natural Gas Filtration, and many more applications, Mid-West Instrument has you covered. Contact us today to discover the ideal differential pressure gauge for your requirements.