Differential pressure gauges have a variety of applications in many different industries. These gauges are specially built to measure the difference between two applied pressures, and they are even able to do the job in harsh conditions and environments. As a result they can be a crucial tool for firms in a variety of industries. Companies in manufacturing, chemicals, energy, and so many other sectors need differential pressure gauges, but they also need to figure out which type is ideal for them.

Ready to order gauges suitable for your industry?

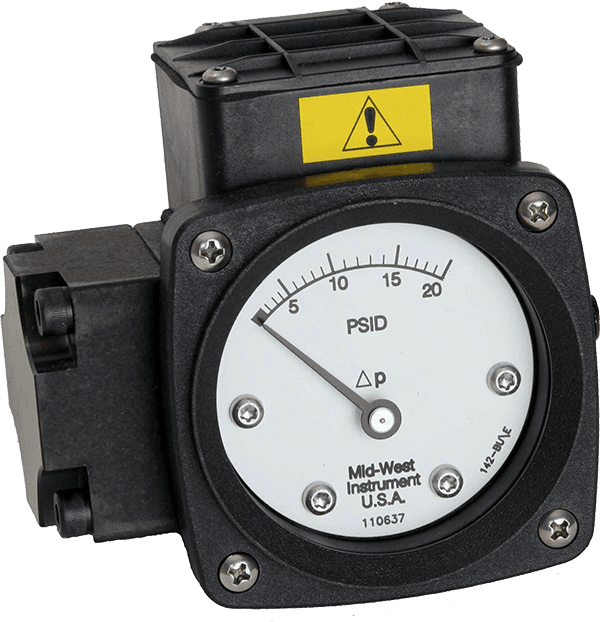

At Mid-West Instrument we offer a few different types of differential gauges. Each offers their own benefits and has their own niche. We’ll help you figure out which works best for you and your industry, and then we’ll lead you right to a product that won’t let you down. Let’s take a closer look at the main types of differential gauges.

Diaphragm Differential Pressure Gauges

As the name implies, this type of gauge uses a single diaphragm. They are primarily built for applications in which both high and low working pressures are involved. A diaphragm pressure gauge can safely measure the difference between two pressures even in extreme conditions. Manufacturers offer a variety of body types and diaphragm seals to match your environment and are graded to work at pressures up to 3,000 psi.

As a result, these types of differential gauges can find a home in harsh industries like the petrochemical sector. A diaphragm differential pressure gauge is equally adept at dealing with high- and low-pressure environments and able to give the accurate readings needed.

Piston-Style Differential Pressure Gauges

A piston-style differential pressure gauge is also quite durable. They are designed to offer a long service life. They can work in rougher environments and survive for years, delivering the accurate information you and your company need.

This particular type of gauge is often used with clean liquid or certain types of gases in an environment where low differential pressure ranges are present. They can also be ideal for measuring liquid levels and flow for companies in many industries. Different types of these gauges, like those with a diaphragm, can also be a bit more versatile and find uses in even more applications.

How to Get in Touch with Differential Gauge Manufacturer

These differential pressure gauges all have their own roles to play and applications that they are best suited for. If you are in need of a certain type of gauge, don’t delay. Our website lists various applications for gauges and offers a helpful product finder that can lead you to the right types of tools. You can also contact Mid-West Instrument at (586) 254-6500 today. We can help you figure out which of these differential pressure gauges will deliver the results you need at your facility or factory.